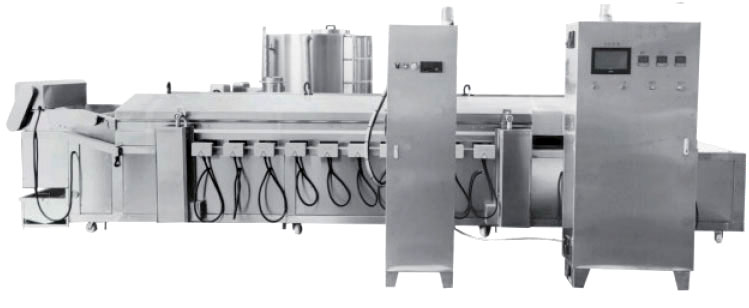

Fully Automatic Continuous Frying Machine

Send Enquire Now The AGICO Fully Automatic Continuous Frying Machine is a high-end core equipment designed for modern food processing enterprises. As a top-tier potato chips fryer machine, we are committed to solving the core pain points of traditional frying methods, such as high energy consumption, rapid oil degradation, unstable product quality, and rising labor costs. Manufactured with precision engineering, this continuous potato frying machine achieves full automation from feeding, frying, oil draining to discharging. It is widely used for potato chips, fruit/vegetable chips, snacks, and prepared foods, making it the ideal choice for building efficient, hygienic, and large-scale production lines.

Send Enquire Now The AGICO Fully Automatic Continuous Frying Machine is a high-end core equipment designed for modern food processing enterprises. As a top-tier potato chips fryer machine, we are committed to solving the core pain points of traditional frying methods, such as high energy consumption, rapid oil degradation, unstable product quality, and rising labor costs. Manufactured with precision engineering, this continuous potato frying machine achieves full automation from feeding, frying, oil draining to discharging. It is widely used for potato chips, fruit/vegetable chips, snacks, and prepared foods, making it the ideal choice for building efficient, hygienic, and large-scale production lines.

Leveraging decades of experience in machinery manufacturing, AGICO integrates exceptional thermal engineering, automatic control technology, and food-grade hygiene standards into every industrial chip fryer, ensuring that every piece of your product achieves perfect uniformity in color, crispness, and flavor.

Components of Potato Frying Machine

The AGICO continuous frying machine is an integrated system comprising several key subsystems that work in harmony. This robust potato frying machine includes:

- Belt Conveying System: For uniform material transport.

- Hoisting System: Facilitates easy cleaning and maintenance.

- Automatic Residues Scraping System: Continuously removes sediment.

- Automatic Control System (PLC + HMI): For precise operation management.

- Hot Oil Circulation System: Ensures even heat distribution.

- Heating System (Electric/Gas/Steam/Thermal Oil): Provides consistent thermal energy.

- Smoke Extraction System: Maintains a comfortable working environment.

Double mesh belt

Double mesh belt Automatic lifting device

Automatic lifting device Filter screen

Filter screen Oil filter device

Oil filter device Oil storage tank

Oil storage tank PLC control box

PLC control boxFeatures of Potato Chips Fryer Machine

- Double-Layer Mesh Belt: Prevents materials from floating, ensuring both sides are evenly fried for perfect results.

- Auto-Lift Function: The mesh belt can be automatically raised, greatly facilitating thorough cleaning and maintenance of the frying chamber.

- Precise & Even Temperature Control: Frying time and temperature can be precisely adjusted via variable conveyor speed and accurate PID controllers, ensuring uniform heat distribution throughout the machine.

- Integrated Oil Filtration & Purging: The oil continuously circulates through a filtration system that removes most residue, while the automatic slag scraping mechanism prevents sediment buildup, protecting oil quality.

- Designed for Production Lines: This machine is engineered to integrate seamlessly into fully automated production lines, working in tandem with upstream and downstream equipment according to your product's specific process.

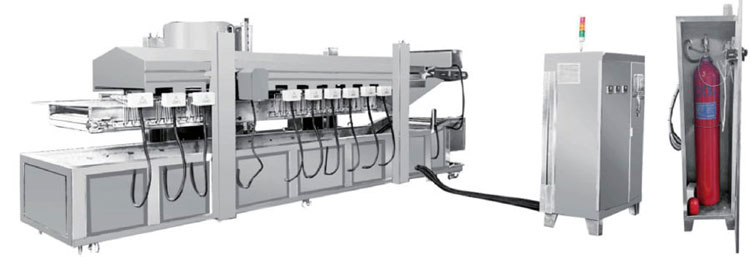

Electric Heating Continuous Frying Machine

Electric Heating Continuous Frying Machine Gas Heating Continuous Frying Machine

Gas Heating Continuous Frying MachineTechnical parameters of Electric Heating Continuous Frying Machine

| Model | Power | Capacity | Weight | Dimension (mm) |

|---|---|---|---|---|

| DDYZ-3500 | 80 kw | 500 kg/h | 1000 kg | 3500×1200×2400 |

| DDYZ-4000 | 100 kw | 600 kg/h | 1200 kg | 4000×1200×2400 |

| DDYZ-5000 | 120 kw | 800 kg/h | 1500 kg | 5000×1200×2400 |

| DDYZ-6000 | 180 kw | 1000 kg/h | 1800 kg | 6000×1200×2400 |

| DDYZ-8000 | 200 kw | 1500 kg/h | 2000 kg | 8000×1200×2600 |

Technical parameters of Gas Heating Continuous Frying Machine

| Model | Burner | Capacity | Weight | Dimension (mm) |

|---|---|---|---|---|

| DCYZ-3500 | 300,000 Kcal | 500 kg/h | 1200 kg | 3500×1200×2400 |

| DCYZ-4000 | 500,000 Kcal | 600 kg/h | 1500 kg | 4000×1200×2400 |

| DCYZ-5000 | 600,000 Kcal | 800 kg/h | 1700 kg | 5000×1200×2400 |

Get a free quote

Get a free quote

Advantages of Potato Chips Continuous Frying Machine

Ultimate Efficiency, Soaring Capacity

This continuous frying machine is designed for 24/7 uninterrupted operation, significantly reducing labor dependency. The capacity can reach up to 2000 kg/hour, making it a high-capacity potato chip fryer machine that easily meets the demands of large-scale orders.

Exceptional, Consistent Quality

Every AGICO potato frying machine is equipped with a PID Intelligent Temperature Control System, achieving oil temperature control accuracy of ±1.5°C. Ensures uniform color and consistent crispness batch after batch.

Energy Saving & Cost Control

Our continuous frying machine features an optimized heat exchanger design, saving 20%-30% energy compared to traditional equipment. Electric heating models achieve an exceptional thermal efficiency of over 95%.

Fresh Oil, Health Assurance

The built-in Automatic Dregs Discharge Mechanism in this industrial chip fryer continuously removes food residues, extending frying oil life by over 25%, ensuring healthier products and pure flavor.

Intelligent Control, Simple Operation

The PLC + Color Touch Screen control system in our potato chips fryer machine allows for one-touch parameter setting and stores multiple product recipes, reducing dependence on skilled operators.

Robust & Hygienic, Long-Lasting

The entire potato frying machine is constructed from food-grade 304 Stainless Steel. The innovative one-touch lift design makes cleaning this continuous frying machine exceptionally convenient.

Contact us for product catalog

Contact us for product catalog

Workflow & Operation

The AGICO Continuous Potato Chips Fryer Machine simplifies the frying process into an efficient, coherent system. Operation is straightforward:

1. Preparation & Startup:

- Add oil to the frying tank until the level reaches the bottom of the upper mesh belt of your potato frying machine.

- Turn on the main power and set the desired frying temperature on the control panel.

2. Continuous Frying Process:

- Once the oil reaches the set temperature, start the mesh belt and begin feeding raw materials into the industrial chip fryer.

- The circulating oil pump ensures even heat distribution and gently pushes the product forward.

3. Oil Management & Purification:

- The automatic residue scraping system in this continuous frying machine actively cleans sediments from the tank bottom.

- An auto-oil replenishment system maintains optimal frying conditions in your potato chips fryer machine.

4. Completion & Discharge:

- The conveyor belt carries the perfectly fried products out, ready for cooling or downstream seasoning.

Application

AGICO Frying Machines serve various global food processing sectors with outstanding adaptability and stability:

- Chips & French Fries: Potato chips, sweet potato chips, composite chips, frozen fries.

- Nutritious Fruit & Vegetable Chips: Banana chips, apple chips, okra, carrot chips, dried shiitake mushrooms.

- Snack Foods: Corn chips, tortilla chips, rice crackers, puffed snacks, nuts (peanuts, almonds).

- Prepared & Instant Foods: Instant noodle blocks, tempura, fried fish balls, chicken nuggets, spring rolls.

Why Choose AGICO?

Profound Engineering Heritage

AGICO is not just a manufacturer but a provider of food engineering solutions. Our engineering team deeply understands your process to offer the optimal configuration.

Comprehensive Customization Service

We never offer a one-size-fits-all solution. Equipment size, heating method, and automation level can be tailored to your factory layout and product characteristics.

Excellent After-Sales Service

We provide global installation, commissioning, operator training, and technical support. Quick response within the warranty period and guaranteed long-term stable spare parts supply give you peace of mind.

Continuous Technological Innovation

We continuously invest in R&D, integrating the latest energy-saving technologies and intelligent control concepts into our products, ensuring your equipment remains technologically leading for years to come.

-lp.jpg)