Sterilizing Kettle Introduction

Sterilizing kettle is applicable to bottled and canned food for secondary sterilization. Following are some sterilizing kettles we can use in common:Revolving Spraying Water (static) Sterilization Kettle

Revolving spraying sterilization kettle sprays hot water with high pressure and high temperature onto surface of packing material of food for quick high-temperature sterilization on various foods. When foods are in high-speed spraying hot (cold) water, temperature of each part will be reduced greatly and effectively. Meanwhile, overheat will be prevented inside of packing of foods.

Working Principle of the Revolving Spraying Water (static) Sterilization Kettle

The product is basketed into the sterilizer and the pot door is closed. The pot door is then secured by a triple safety interlock. Throughout the sterilization process, the door is mechanically locked. The sterilization process is carried out automatically according to the recipe input to the microprocessor controller PLC.Keep the right amount of water at the bottom of the sterilizer. If required, this water can be injected automatically at the beginning of the heating phase.

In the heating and cooling phase of tubular heat exchangers, the process water in the pot passes through one side, while the steam and cooling water pass through the other side so that the sterilized product will not come into direct contact with the steam and cooling water, achieving sterile heating and cooling.

Revolving Spraying Water (static) Sterilization Kettle Features:

- The alloy mechanical seal is adopted to solve the problem of water vapor leakage during rotation.

- The carrier wheel is made of tin bronze, stainless steel, synthetic steel, and other materials, which prolongs its service life and solves the defect of rotating with bearings.

- The guide rails all adopt rollers, distributed in the left, right and lower parts, which reduces the labor intensity of workers in the process of feeding and discharging, and prevents the phenomenon of the material basket loaded with products in the rotation process back and forth.

- The transmission system adopts a reducer with a braking function and an automatic positioning system to ensure that the rotating body always maintains the same position after stopping, which is convenient for the smooth feeding and discharging process.

- The rotation speed adopts frequency conversion speed regulation, and the user can adjust the rotation speed of the rotating body at any time according to the different viscosity of the product, to achieve the purpose of non-delamination and non-precipitation of the product.

- The equipment and the reducer base are made as one.

- The whole sterilization process adopts PLC automatic linear control, the heat distribution temperature in the tank is controlled at ±0.2 °C, multi-stage heating, energy saving, equipped with F value measurement function, can store 100 sterilization formulas.

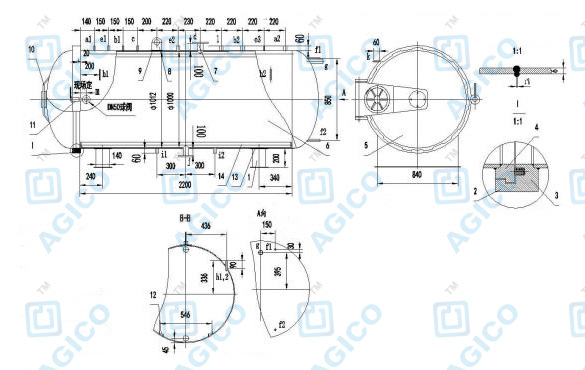

The horizontal sterilizing kettle

The horizontal sterilizer kettle is applicable for sterilizing the tinned oral liquid, meats, cans, beverage and medicine in high temperature. At the same time it can test and conduct a vacuum test after the canning, locking and sterilizing .This sterilizing kettle uses the round cylinder taking the compressed air as reaction force. The canned materials can be cooled quickly and used compressed air as reaction force to keep the glass bottle from breaking, its cap falling off and loosing after they have been sterilized in the pot.

|

|

Double baths sterilizing kettle

Hot water cycle type bacteria killing kettle can preheat the up-tank to the required temperature before working, put the water in the up-tank to the down-tank quickly, and according to the flows of pump, steam direction set up hot water separation devices, through the large pumps and large calibra pipes, put water in the pot after spray equipment four cycles rapidly, reach sterilization without dead ends, false ends, and can avoid the phenomenon of overheating around the foods, make the food sterilization fast and accurately.

|

|

Full-function retort suitable for all kinds of high-temperature packaging materials:

- plastic containers: PP bottles, HDPE bottles.

- soft bag packaging: aluminum foil bag, transparent bag, vacuum bag, high-temperature cooking bag, etc.

- metal containers: tinplate cans, aluminum cans.

- glass container.

Steps to Use the Sterilizing Kettle

- First, take out the inner sterilization bucket, and then add an appropriate amount of water to the outer pot to make the water surface level with the triangular shelf.

- Return the sterilization bucket and fill the items to be sterilized. Be careful not to pack too much, so as not to hinder the steam flow and affect the sterilization effect. The triangular flask and the end of the test tube mouth should not be in contact with the barrel wall, so as to prevent condensation from wetting the paper at the mouth and penetrating the cotton plug.

- Cap and insert the exhaust hose on the lid into the exhaust tank of the inner sterilization bucket.

- Then tighten the two opposite bolts at the same time in a symmetrical manner to make the bolts tighten and prevent air leakage.

- Heat with an electric stove or gas, and at the same time open the exhaust valve, so that the water boils to remove cold air from the pot. After the cold air is completely exhausted, close the exhaust valve and let the temperature in the pot gradually rise as the steam pressure increases. When the pressure in the pot rises to the desired pressure, control the heat source and maintain the pressure for the desired time.

- After the time required for sterilization is up, cut off the power or turn off the gas, and let the temperature in the sterilization pot drop naturally, when the pressure of the pressure gauge drops to 0, open the exhaust valve, loosen the bolt, open the lid, and take out the sterilized items.

Maintenance of the Sterilizing Kettle

The sterilization pot should be inspected regularly, at least once every six months for external inspection, and at least once a year for inspection, the preparation work and inspection items before inspection are carried out in accordance with the "regulations" and relevant regulations, and the inspection report is archived for the record. If the sealing ring on the flange surface of the pot body is aging, defective, and worn, it should be replaced in time. When the equipment is not in use, the inner and outer surfaces of the sterilization pot and the lid should be cleaned, the exposed processing surface should be brushed to prevent rust paint, and the safety detection and control instrument should be covered and protected.

Packing and Delivery

-lp.jpg)