Plant Protein Beverage Introduction

Plant protein beverage is a kind of emulsion beverage , which is produced after processing and mixing then sterilization by high pressure from plant nuts, pulp and soybean(such as soybean, peanut, almond, walnut kernel, coconut).

Our company is committed to the complete line of the plant protein beverage. According to different raw materials, plant protein beverage can be divided into four broad types (soy milk, coconut milk, almond milk and walnut milk) and other plant protein beverages. Our team of technologists and engineers will provide a feasible solution for the specific process application to meet client’s requirements.

Send Enquire Now!

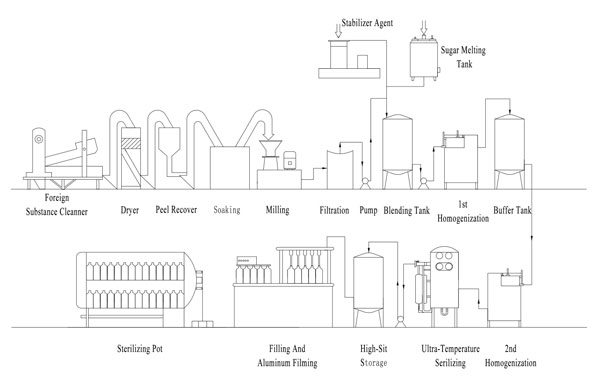

The processing line is composed of the following phases:

Processing for raw material, drying, soaking, milling, separation, filtration, blending, homogenization, degassing, cooling and storage, sterilization, aseptic filling and packing.

This production can be used to produce soy milk, coconut milk, almond milk, walnut milk and peanut milk etc. they can be packaged to bottled drinks or boxed drinks.

Plant Protein Beverage Line Flowchart

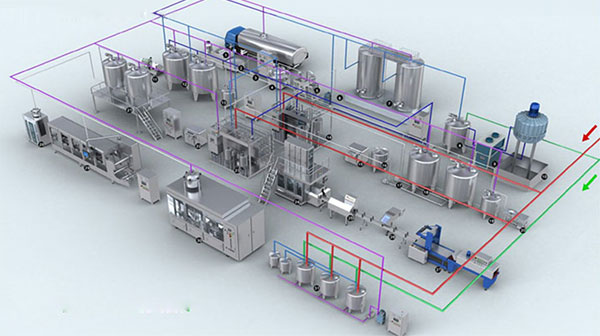

Plant Protein Beverage Processing Equipments

(Storage Tank-Colloid Mill-Filter-Blending Tank-High Pressure Homogenizer-Vacuum Degasser-UHT Sterilizer-Filling and Packing Machine-Continuous Spraying Sterilizer-Case Packer).

Substance cleaner:It is mainly used to remove floating dust and microorganisms on the surface of plants, filter out sand, moldy plants, and separate impurities such as stones and metals. It is made of SUS304 material and has a capacity of 100kg to 500kg per hour.

Soaking machine:The purpose of soybean soaking is to soften the cell structure, improve the dispersion and suspension of the colloid, and increase the protein yield. Hot water soaking is often used in industrial production, which has good continuity and high efficiency. This bean soaking machine is composed of a bean storage bucket, a bean soaking tank, a draining net, a rack and a pipeline. The equipment is made of SUS304 material.

Peeling machine: The peeling machine is suitable for blanching nuts and removing the brown skin on the nuts. The whole machine is made of SUS304 material. The peeling rate is as high as 98%, and the broken rate is less than 1%. The nuts are soaked in the hot water in the feeding hopper for 5-7 minutes, and then sent to the rubber wheel, the rotating rubber roller will rub the nuts, and easily peel off the soft nut skin.

Blending tank: The function of the mixing tank is mainly to mix various beneficial substances such as nut paste, syrup, emulsifier, etc. into a certain volume according to a certain formula. The tank is made of SUS304, which can be heated by steam or electric, and is easy to use and maintain. The dosing accuracy of ingredients determines the final product quality. The tanks are equipped with load cells to ensure that each ingredient enters the mixing tank according to the recipe.

Contact us for more information!Plant Protein Beverage Processing line Characteristics

- The production capacity of the plant protein beverage production line is 1000 to 40000 L/H

- Easy and convenient operation.

- Better environmental compliance.

- Convenient CIP system, lower maintenance.

- All parts in touch with raw materials are made of 304 stainless steel, Complete comply with food safety and hygienic requirements.

Plant Protein Beverage benefit

Compared with carbonated drinks, fruit juice drinks and tea drinks, plant protein beverage has a higher nutritional value. The health value of the plant protein beverage depends on different raw materials. Soy milk plays an outstanding role in the plant protein beverage, it contains almost as much as protein as cow’s milk, yet is low in calories than whole milk and comparable to skim milk, so it suitable for all ages, especially for the person with hyperlipidemia and high cholesterol. Almond has the effect of lungs and cough, so almond milk suitable for little kids with coughing usual. Known as brain-healthy and skin lotion, walnut is believed to improve intelligence, so drinking walnut milk is of great benefit to these who use brain usual.

.jpg)

.jpg)

.jpg)

-lp.jpg)