Falling Film Evaporator Description

In beverage field, falling film evaporator is a widely applicable in concentration of glucose, starch sugar, maltose, milk, juice, vitamin C and other aqueous solution. Continuous low-temp evaporation under vacuum to ensure saves energy and time with low loss and convenient to keep product color, taste and nutrition. It can satisfy the continuous production requirements.

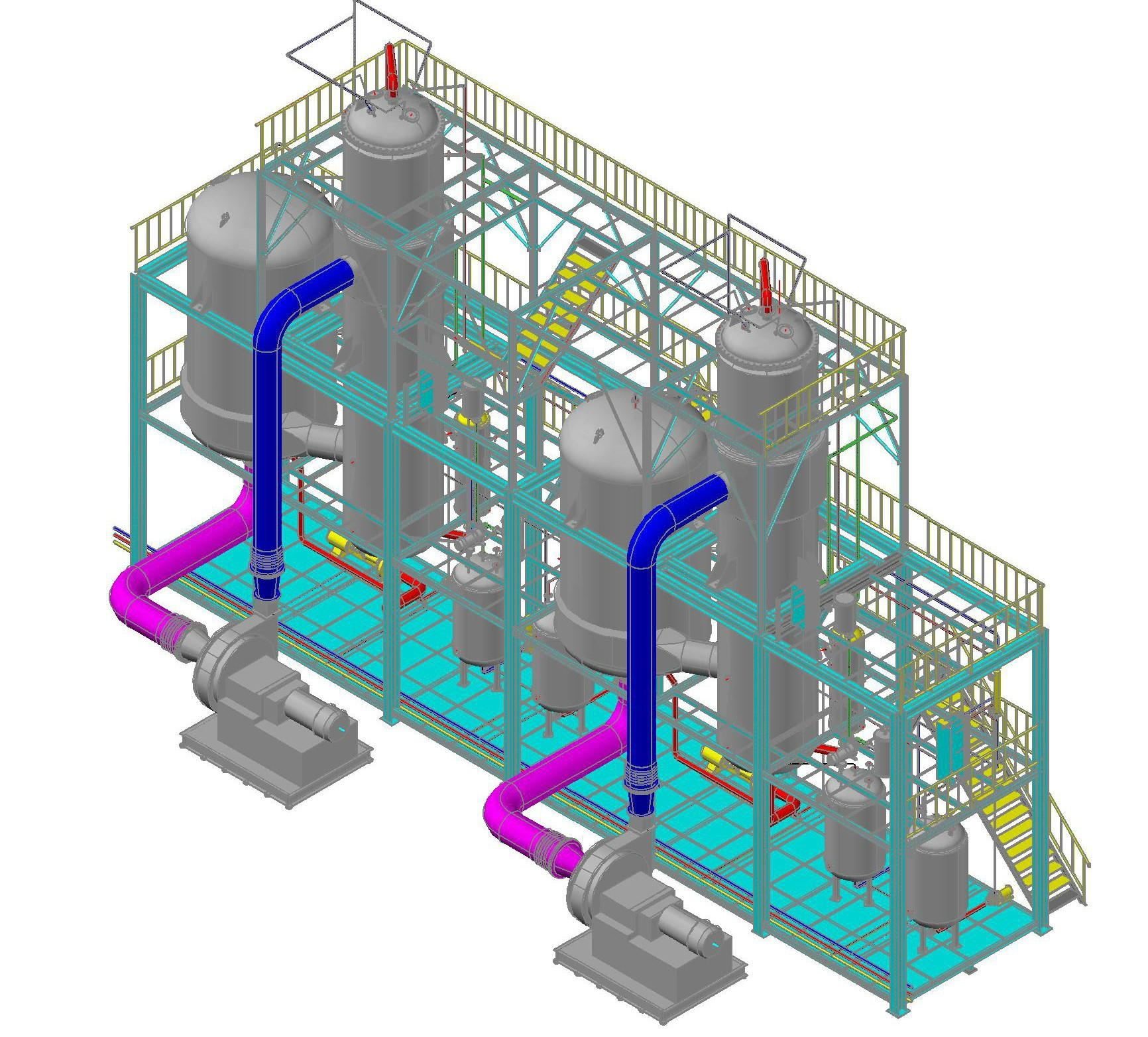

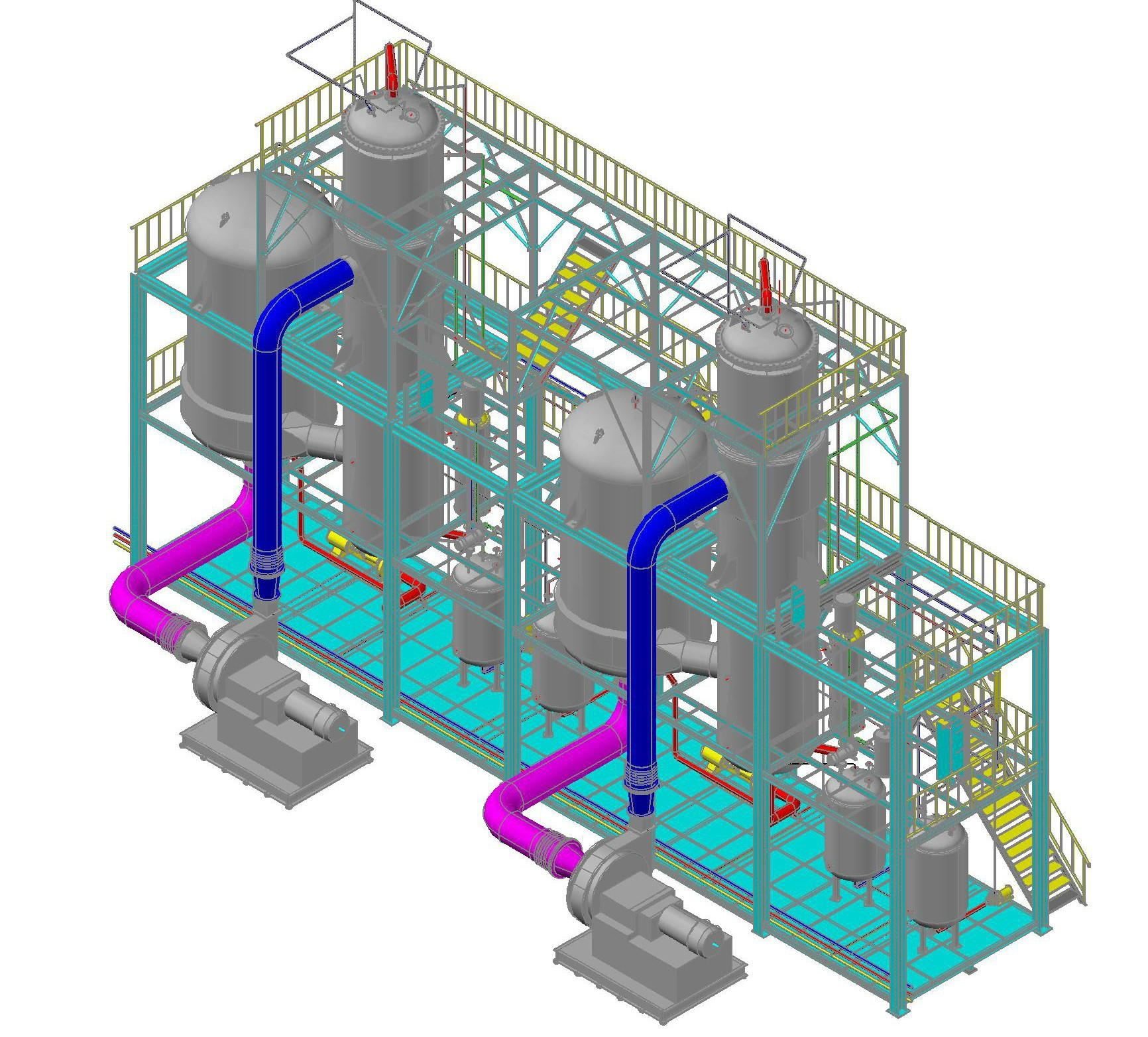

Falling Film Evaporator Structure

Falling film evaporator consists of (first-effect, second-effect, third-effect)separators and evaporators and pre-heaters, condenser and vacuum pump, feeding pump, circulation pump, discharge pump, condensed water pump, pipeline and fittings, etc. It is equipped with CIP spraying cleaning ball, vacuum gauge, thermometer, pressure gauge, and so on.

Working Principle of the Falling Film Evaporator

The material that needs to be evaporated enters from the top through the feed pump, takes the evaporation tube (pipe process), the material is distributed to the heat exchange tube in the form of a film through the membrane spreader, and the material is heated by the steam outside the tube when it flows down the tube cavity by gravity, and evaporation occurs after reaching the evaporation temperature, and the material and the secondary steam flow down from the tube to evaporate in the form of a film. After the secondary steam is compressed by the steam compressor, it is sent to the shell of the falling film heating chamber as heating steam.

Falling Film Evaporator Features

-

Evaporation capacity: From 500Kg/h to 80T/h.

-

It can be also used together with the coercive circulation evaporator and crystallizer to deal with the concentration and product crystallization of high viscous and easy scaled material.

-

It is characterized by high efficiency of heat conduction, low power consumption etc.

-

It can widely use the waste heat (such as the drier's hot air and flue gas), the remaining heat (of condensing water, process water and flash steam) to form a waste heat evaporation machine unit.

-

Large concentration ratio: adopt falling film evaporation, which make the material liquid with larger viscosity be easy to flow and evaporate, hard to scale, short concentration time, the concentration ratio can reach to 1:5.

-

This equipment can realize automatic production, intellectual system management.

-

Can be designed into different technological process according to the different characteristics of the materials and different users' requirements.

-

The equipment can operate continuously.

-

The equipment is equipped with CIP cleaning pipeline, which can realize local cleaning, and the whole set of equipment is convenient to operate without dead angles.

-

The large equipment adopts a vertical floor-to-ceiling structure, and the whole set of equipment has a compact structure and a small footprint.

Technology of the Falling Film Evaporator

By Adopting the falling film evaporation form, the equipment is used for concentration and evaporation of fruit and vegetable juices and other heat sensitive materials. The evaporation system can be made up of single-effect, 2-effect, 3-effect, 4-effect, 5-effect, 6-effect according to the property of compressed material and customer's request.

It can be also used together with the forced circulation evaporator and crystallizer to deal with the concentration and product crystallization of high viscous and easy scaled material. It is characterized by high efficiency of heat conduction, low power consumption etc.

-lp.jpg)