Vacuum Degasser Introduction

Vacuum degasser is the device that excludes non-condensable gases contained in the feed solution by vacuum suction, it is essential degassing equipment which is used in dairy products, fruit juices and other materials processing line. It is removing the gas attaching to the suspended particulates, stopping the particles upping, and at the same time prevent browning and oxidation, so as to improving the looking, reducing bubbles in high temperature sterilizing and filling. Normally, vacuum degassing is after homogenizing and sometimes, is before filling.

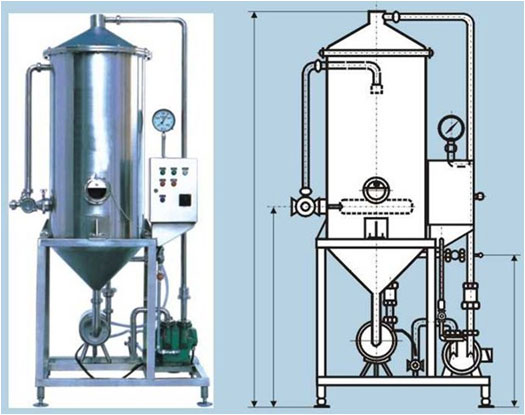

Main Structure and Working Principle of the Vacuum Degasser

|

|

Vacuum Degasser Features

- It’s main components are degas chamber, condensers, vacuum pump and etc.

- Degassing rapidly and thoroughly.

- Can add specific gas recovery unit for options.

- Working in series with sterilization machine.

- Control system can be divide into manual control and automatic control.

- The equipment is easy to install, safe and reliable, and easy to maintain.

- The working time and cycle of the degasser can be adjusted as needed.

- Due to the removal of oxygen from the water, the equipment will last longer.

Steps to Use the Vacuum Degasser

When used, as long as the matching vacuum pump is turned on, the air in the device is pumped out, and the material enters the device from the inlet itself, when the material rises to a certain position, the control valve automatically controls the material, at this time you can observe and control the feeding speed from the sight hole, when the vacuum degree in the device reaches the process requirements, the material can be pumped out from the material outlet, as long as the balance of vacuum degree and inlet and outlet is maintained, production can continue.

Operation and Maintenance of the Vacuum Degasser

- Before and after use, clean the inside of the equipment with hot water (90--95 °C) and treat it with steam.

- Regular maintenance, when the sealing ring is found to be aged and damaged, it should be replaced in time.

- When using, keep each sealing part good, and there should be no air leakage.

- Always check the diaphragm pressure gauge to keep it accurate.

| Model | VD-1.5 | VD-2.5 | VD-5 | VD-10 |

|---|---|---|---|---|

| Capacity(T/h) | 1.5 | 2.5 | 5 | 10 |

| Power(Kw) | 2.2 | 2.2 | 4 | 15 |

|

Vacuum degree (Mpa) |

-0.08~-0.0906 | |||

Packing and Delivery

-lp.jpg)