AGICO Coconut Meat Drying Oven

WhatsApp

WhatsApp

As a professional manufacturer of food processing equipment, AGICO is dedicated to providing efficient and energy-saving drying solutions for global clients. Our CT-C series hot air circulation drying ovens, integrating cutting-edge heat pump technology and intelligent control systems, are specifically designed for coconut meat, coconut chips, and various fruits and vegetables. They aim to achieve high-quality, large-scale, and uninterrupted modern production, completely revolutionizing traditional drying methods.

Advantages of the Coconut Dryer Machine

The AGICO Coconut Meat Drying Oven is not just a drying device; it is a complete production system that ensures product quality and enhances economic efficiency.

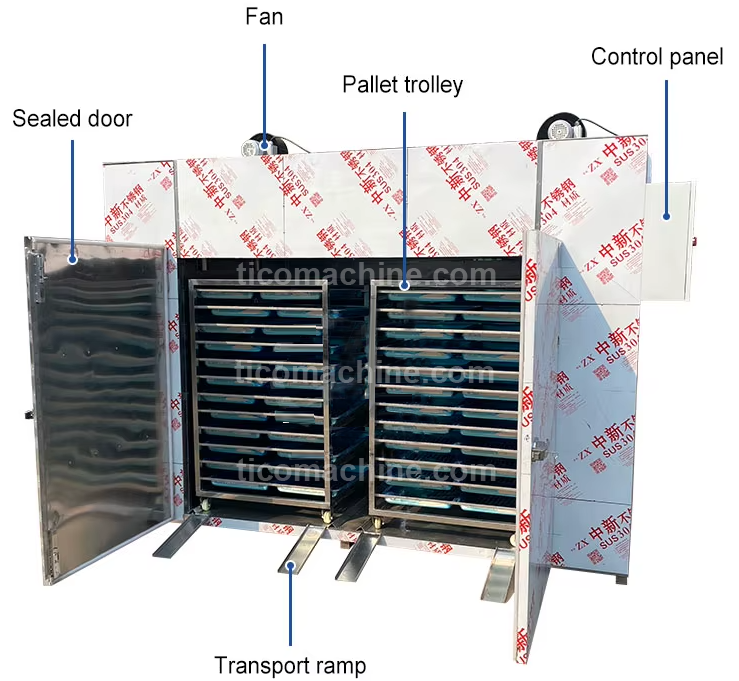

Struture of dryer machine

Struture of dryer machineEnergy Efficiency:

Utilizing our proprietary fully enclosed hot air circulation system, the thermal efficiency of the drying process is increased from 3%-7% in traditional drying rooms to an impressive 45%-50%, with a maximum of 60%. This translates to significantly reduced energy consumption and operational costs for you while achieving the same drying results.

Precise and Uniform Drying:

The chamber is equipped with low-noise, high-temperature-resistant axial flow fans and adjustable air distribution plates, creating a planar circulating air duct that ensures highly uniform temperature distribution (temperature difference between top and bottom ≤ ±2°C) and 360° dead-angle-free air supply. This guarantees that every batch of coconut chips dries evenly, resulting in a consistently white color and well-preserved active nutrients.

Fully Automated Intelligent Control:

Integrated with an advanced touch screen and PLC automatic temperature control system. Users can easily set and store drying curves (temperature range 50-140 °C with steam heating). The entire process, from the initial low-temperature drying phase (45-60°C) to subsequent gradual temperature increases, is intelligently regulated without manual supervision, offering simple operation and stable quality.

Cleanliness and Safety:

Materials are dried entirely within a closed, clean environment, completely isolated from external contamination. The equipment is designed following the pharmaceutical industry " GMP; standards, featuring a unique guide rail sealing mechanism and a quick-disassembly inner chamber design. This ensures airtightness and allows for thorough cleaning and maintenance, meeting the hygiene requirements of high-end food processing.

Adaptability and Multi-Purpose Use:

In addition to coconuts, the equipment is equally suitable for drying a wide range of materials, including lemons, mangoes, bananas, chilies, Chinese medicinal herbs, and flowers. One machine serves multiple purposes, helping clients flexibly schedule production and maximize return on investment.

AGICO Coconut Meat Drying Oven Models

Contact us for product catalog

Contact us for product catalog

The AGICO CT-C series offers a range of models to meet various capacity needs, from small and medium workshops to large processing plants. Below are specifications for some standard models. We can also provide customized designs based on your specific requirements.

| Industry Standard Model | Model | Batch Drying Capacity (kg) | Installed Power (kW) | Steam Consumption (kg/h) | Number of Baking Carts (sets) | Overall Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|

| RXH-14-C | CT-C-Ⅰ | 100 | 0.45 | 18 | 2 | 2300×1200×2000 |

| RXH-27-C | CT-C-Ⅱ | 200 | 0.9 | 36 | 4 | 2300×2200×2000 |

| RXH-41-C | CT-C-Ⅲ | 300 | 1.35 | 54 | 6 | 2300×3220×2000 |

| RXH-54-C | CT-C-Ⅳ | 400 | 1.8 | 72 | 8 | 4450×2200×2000 |

Coconut Meat Before Drying

Coconut Meat Before Drying Dried Coconut Meat

Dried Coconut MeatCoconut Chips Drying Production Line

The AGICO drying oven is the core component of an automated coconut chip production line. A typical process for candied coconut chips is as follows:

Raw Material Selection → Dehusking & Peeling → Slicing → Cooking (in sugar-salt water) → Rinsing → Centrifugal Dehydration → AGICO Intelligent Drying → Cooling & Packaging

Contact us for product catalog

Contact us for product catalog

In the drying stage, the equipment can rapidly and uniformly reduce the moisture content of pre-treated coconut slices to below 8%, while effectively locking in the natural aroma and sweetness of the coconut meat. The finished product boasts a moist white color and neat chip shape, significantly enhancing the product's market value.

Service and Support

AGICO firmly believes that high-quality equipment must be backed by reliable service.

- Customized Design & Production: During the design and production process, we fully consider your workshop layout and utility conditions (water, electricity, steam) to ensure the equipment is delivered in its optimal configuration.

- Professional Installation & Commissioning: Upon equipment arrival, we will dispatch dedicated engineers to guide on-site installation and commissioning until the equipment is operational (professional remote video guidance is also available depending on the situation).

- Comprehensive Operational Training: Before formal production begins, our engineers will provide systematic training for your relevant personnel, covering equipment operation procedures, routine maintenance, and common troubleshooting.

- Comprehensive Quality Assurance: All equipment comes with a full one-year warranty. During the warranty period, malfunctions caused by non-human factors will be repaired or replaced free of charge.

- Lifetime Technical Support: We promise to provide lifetime technical consultation support for the equipment and supply high-quality spare parts at competitive prices.

Contact AGICO now for a customized solution and quote!

Let the AGICO CT-C series hot air circulation coconut meat drying oven become your powerful partner in improving quality, reducing costs, and expanding capacity. Our professional team is always ready to serve you and explore new market opportunities together.

Automatic Coconut Cutting Machine

Automatic Coconut Cutting Machine Tender Coconut Half Cutting Machine

Tender Coconut Half Cutting Machine Manual Coconut Cutting Machine

Manual Coconut Cutting Machine-lp.jpg)