Introduction of lychee juice processing plant

Lychee, also known as litchi, is rich in nutrients. It contains glucose, sucrose, protein, fat, vitamin A, B and C, and also contains various nutrients such as folic acid, arginine and tryptophan, which are very good for human health. The food processed by litchi is very popular, including lychee juice, litchi jam, litchi wine and so on.

Send Enquire Now

Send Enquire Now

Our lychee processing plant can be used for processing lychee, longan and other fruits, they can be processed into fruit juice, fruit jam, fruit wine and etc. The lychee processing line includes lychee washing machine, peeling machine, jam making machine and other machines.

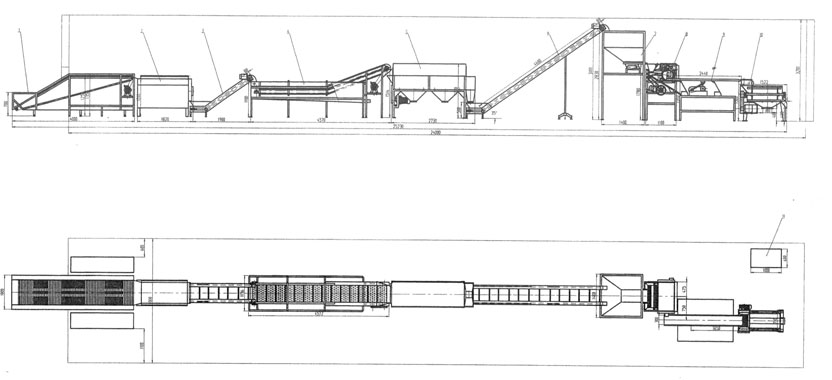

We can customize lychee juice processing line or fruit processing plant according to your needs. The following picture is exactly a lychee juice and wine processing plant, which is one of our customers' projects.

Complete line of lychee juice line

Characteristics of lychee and longan processing plant

- Lychee and longan processing plant can automatically grade, clean, sterilize, peel, remove seeds, make jam and press juice, then ferment to become lychee wine, fill to get finished product. It is widely used in the downstream processing of lychee and longan juice and fruit wines.

- This is an ideal plant to process lychee, we can customize the plant according to customer’s requirements and actual situation.

- The quality of the finished products is stable and can be up to the Chinese hygienic standard for foods.

- Lychee and longan peeling, seeds removing and jam making technology and equipment was a research project which belongs to China Spark Program and transfer of scientific and technology of China. We got two patents for the equipment, in 2005, the equipment passed the Appraisal of Scientific and Technological achievements; in 2006, the equipment received Provincial Third Prize of Scientific and Technological Advancement Award, and Provincial Third Prize of Agricultural Technology Extension Award.

The production process of lychee juice

Feeding→Pre-Grading→Cleaning→Water Dropping→Grading→Peeling→Fine Grading→Jam Making→Juice Pressing→Ferment→Filling→Finished Product→Packing

Contact us for product catalog

Layout for 2-3T/H lychee jam processing plant

Roller style fruit selector→Brush washing machine→Belt conveyor→Water bubble washer→Fresh fruit grading machine→Belt conveyor (LZT3)→Mid-storage silo→Peeling machine→Vibrating conveyer→Jam making machine→Fruit nut conveyor→Fruit peel conveyor→Electric control panel

Contact us for product catalog

Main equipments of lychee processing plant

A complete litchi processing plant includes the following equipment. Sometimes, it need to be equipped with a storage silo, vibrating convryor, jam making machine, etc. We can customize the litchi processing plant according to your specific needs.

- Roller fruit sorting machine

- fruit surfing washing machine

- brush and spray cleaning machine

- scraper fruit elevator

- litchi/longan peeling machine

- litchi/longan core removing machine

- fruit pulper machine.

Lychee peeling machine

Lychee peeling machine Roller style fruit selector

Roller style fruit selector Brush washer

Brush washer Water bubble washer

Water bubble washer Lychee fruit grading machine

Lychee fruit grading machine Feeding conveyor to peeling machine

Feeding conveyor to peeling machine Vibrating conveyor for peeled lychees

Vibrating conveyor for peeled lychees Conveyor for peels

Conveyor for peelsElevator

Be used to lift the fruit and vegetables into the next procedure. Transporting the fruit by moving the clapboard up under the drive of motor. The material of the clapboard: supporter is made of SUS304 stainless steel, the clapboard is made of stainless steel or plastic PP (polypropylene), which is applicable for all kinds of fruit and vegetables.

Roller style fruit selector

Bad quality fresh lychees are picked up by manual.

The equipment is suitable for sorting ball-shaped or long round fruits and vegetables. The fruits rotate on the rolling rod to ensure the fruit sorting quality.

Spraying device and water collection trough can be designed according to requirements.

Waste fruit collecting and conveying device can be designed according to requirements.

Clearances between different rolling rods used for materials sorting can be designed according to requirements.

Dimensions can be designed according to requirements.

Brush and spray cleaning machine

Removing of extraneous matters and eliminating the stickiness contained on most of the lychees' peels. The brush roller spray cleaning machine uses brushes to remove dirt and hair from the surface of the fruit. The bottom of the machine is conical and equipped with a drain for easy removal of sediment. It is suitable for round, cylindrical and irregularly shaped vegetables and fruit.

Fruit bubble washing machine

Washing fresh vegetable and fruits and lychee. The bubble washing machine is an ideal cleaning equipment for the food industry such as fruit, vegetables, meat, etc. It is equipped with a bubble generating device to keep the material in a rolling state and remove pesticide residues on the surface of the product. The floating matter can overflow from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning.

Lychee peeling machine

Peeling off skins of lychee (longan) without twig. This machine is pre-treatment equipment for lychee wine and beverage, dry lychee or canned lychee. It is usually used to peel off the shell from lychee.

The peeling rate of this machine is more than 99% and the loss of pulp is less than 1%.So it is the ideal equipment for fruit wine and juice industries.

Introduction of lychee processing machinery

|

No.

|

Equipment name

|

Picture

|

|---|---|---|

|

1

|

||

|

2

|

||

|

3

|

Brush and spray cleaning machine

|

|

|

4

|

||

|

5

|

Lychee peeling machine

|

|

Features:

- The material of the lychee processing machine is made of food grade SUS304 material, which can guarantee to produce premium end products.

- The whole processing line is fully automatic, PLC controlled, high degree of automation and high efficiency.

- Strong processing capacity.

- Maximum preservation of lychee's flavor and nutrients.

- The production line equipment is specially designed and customized according to the characteristics of lychee, and the output is high.

End products:

|

.jpg) |

.jpg) |

.jpg) |

Successful case

.jpg)

-lp.jpg)