Fruit Bubble Washing Machine Principle

The blower runs the air through tank-washer and makes the water keep rolling, because of the rotation, rapid flow scour the surface of the raw materials and wash the dirt out. Blending by air, fruit washing machine can wash the dirt quickly and not break fruits under acutely rotation, so it suited for cleaning fruits and vegetables. Fruit washing machine in all the fruit juice processing line is important.

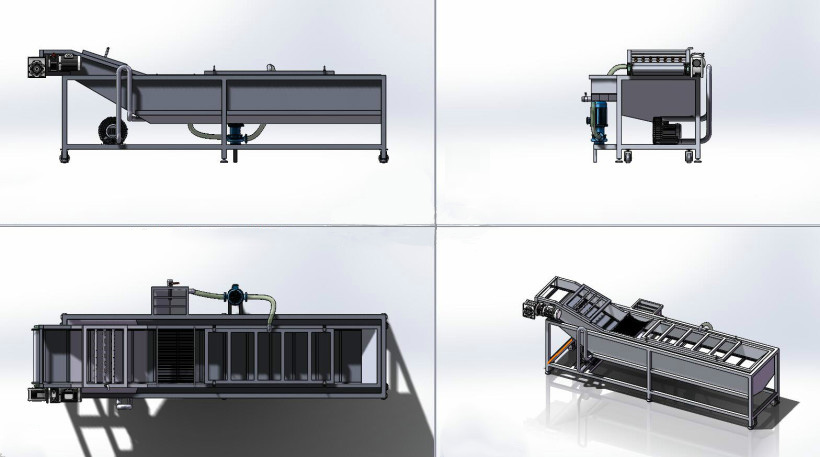

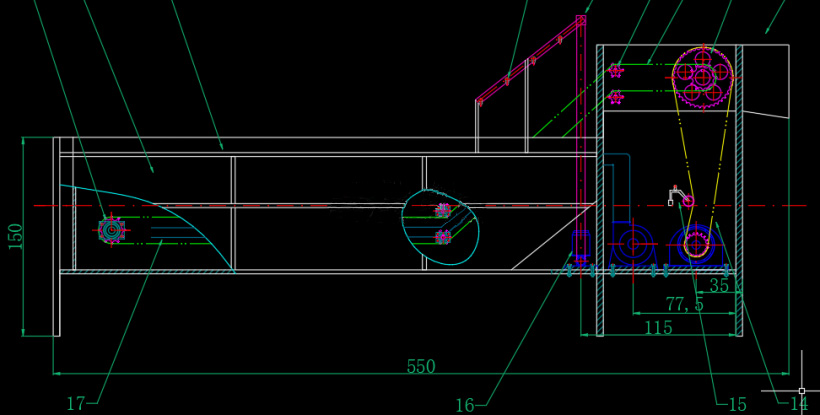

Fruit and Vegetables Washer Machine Structure

Fruit and vegetables washer machine mainly consists of tank, upender, blower, roller, spray water tube, hopper and etc, and widely used in washing various kinds of fruits and vegetables.

Fruit Bubble Washing Machine Features

- By air blending, fruit washing machine can wash the raw materials quickly and protect completeness of the raw materials.

- Control system used technology of frequency scaling and seamless shifting, PLC automatic control, can achieve coordination of downstream equipments. Stable operation, noise level lower 80 DB.

- The raw material was rushed to elevator by circulating water, and sent to next step.

- Washing water can be recycling after filtered.

- The frame is made of SUS304 stainless steel, which meets the standards of the food industry.

- Every single machine in the assembly line can be customized according to the different processing characteristics of users, and meet the process requirements to the greatest extent.

- The machine has a compact structure and a high degree of automation, which is suitable for use in various processing-scale enterprises.

Fruit Washing Machine Application

How to wash fruit? Fruit washing machine is widely applicable to wash apples, oranges, tomatoes, mangoes and etc.

This is the parameter table of the product.

| model | Production Capacity T/h | Power KW |

| AGICO-20 | 20-40 | 6.3 |

| AGICO-10 | 10-15 | 4.45 |

| AGICO-5 | 4-8 | 3.15 |

| AGICO-2 | 1-2 | 1.67 |

AGICO provides you with the operating steps of the fruit bubble washing machine:

- Clean the water tank, fill it up with water, and pour clean water into the main tank until water flows out from the overflow port.

- Start the conveyor belt motor to make the mesh belt operate normally and in the correct direction.

- Start the vortex pump to churn the water in the tank.

- Open the spray pipe valve so that the water is sprayed evenly on the mesh belt.

- Check the running parts of the machine and make sure that they are operating normally.

|

|

AGICO makes a solemn promise to you:

Product quality commitment

The manufacture and testing of the products are documented.AGICO conducts the whole process and full performance inspection of the product before packing and shipping.

Product price commitment

Our company sincerely provides you with a preferential price without reducing the technical performance of the product or changing the product parts.Product pre-sales service:

Provide consulting services to customers, and provide customers with project design and process design. Design and manufacture products according to your special needs and train technical operators for you.Product in-sale service:

AGICO technicians remotely guide the equipment installation, provide round-the-clock telephone service, and provide service as usual on holidays.Product after-sales service:

Obtaining customer satisfaction is our service goal.During the warranty period, AGICO will repair and replace parts that are naturally damaged due to time free of charge. If the parts are damaged outside the warranty period, the parts we provide will only charge the cost.

-lp.jpg)