Pineapple Juice Processing Line

If you want to build a pineapple juice complete production line, there are some juice making machines are indispensable just as the following:

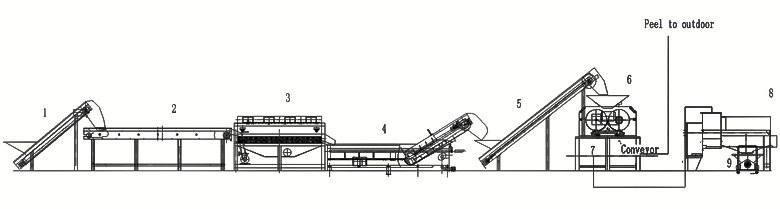

Fruit elevator---Fruit sorter--- Brush type citrus cleaning--- Fruit bubble washing machine---Fruit elevator--- Pineapple peeling and squeezing---Fruit pulping

The Workflow of Pineapple Juice Processing Line

1. Fruit elevator 2. Fruit sorter 3. Brush and spray cleaning machine 4. Fruit bubble washing machine 5. Fruit elevator

6. Peeling and squeezing machine 7. Pump Ⅰ 8. Pineapple pulper 9. Pump Ⅱ

The flowchart is the processing line of pineapple juice making machine. As the picture shows that the fruits washed firstly by using fruit bubble washing machine, then the bad ones are picked out, to make sure that the fruits to be processed are of good quality. Those good ones are extracted and pulped. The pineapple juice making machine is the main equipment in this production line which is responsible for extracting the pulp and juice from the fruits.

End products:

|

.jpg) |

.jpg) |

Main equipment of the pineapple juice complete production line

We can design and manufacture whole pineapple juice processing line according to your requirement. The capacity of pineapple juice complete production line can be 5T-15T/H.

|

No.

|

Equipment name

|

Picture

|

|---|---|---|

|

1

|

||

|

2

|

||

|

3

|

Brush and spray cleaning machine

|

|

|

4

|

||

|

5

|

||

|

6

|

Elevator

Be used in the low or high level lifting and conveying of fruit and vegetables. AGICO fruit elevator is composed of a bracket, a bucket, a motor and an engineering plastics mesh belt. The bracket is made of SUS 304 stainless steel with sturdy structure. The motor adopts stepless speed adjusting device.The engineering plastic mesh belt adopts a modular structure, which has little damage to the conveyed materials. In addition, our fruit elevator is easy to clean.

Rolling rail fruit sorting machine

Sorting of pineapple by hand. Fruit sorting machine is professional equipment for pineapple sorting. The pineapple moves forward and rotates simultaneously on the stainless steel roller. Staff can easily find defective fruit and remove it.

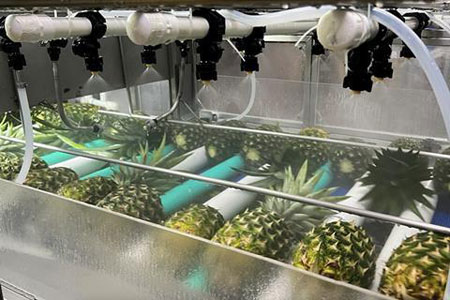

Brush and spray cleaning machine

Removing of extraneous matters and eliminating the stickiness contained on most of the pineapples' peels. The brush and spray washing machine is ideal for cleaning round fruits and vegetables. It is widely used to wipe away dirt and pesticides on the surface of fruits or vegetables, such as apples, pears, lychees, oranges, pineapples, etc. This unit can be used alone or with other cleaning equipment.

Pineapple brush and spray cleaning machine

Pineapple brush and spray cleaning machine Pineapple bubble washing machine

Pineapple bubble washing machineFruit bubble washing machine

Washing fresh vegetable and fruits and pineapple. Fruit bubble washing machine is mainly used to clean fruits. Fresh and clean fruit is essential for making healthy and delicious juice. Therefore, the fruit washing machine is the key equipment for the production of juice. AGICO fruit bubble washing machine is suitable for cleaning all kinds of fruits, such as oranges, mangoes, pineapples, lemons, etc.

Peeling and squeezing machine

Remove the peel out of pineapple, and extract the juice on the first time. When pineapples are fully cleaned up, they are fed into pineapple peeling and squeezing machine. There are knives cutting the pineapples into half, and a scraper separating peels and pulps. Then the pineapple pulp and roughly extracted juice are conveyed to the next process, and fruit peels are discharged through the outlet.

Pineapple pulper

Destoning and pulping of pineapples. Pulping machine is used to pulp different fruit and vegetables. It is an ideal device for making juice. It separates the juice from the peel and the seeds inside the fruit, and the juice can be used in the next process, leaving the peel and seeds as residues.

Features of pineapple processing plant

- The pineapple processing plant has a high degree of automation, first-class configuration, and meets food-grade hygiene standards.

- Strong processing capacity.

- The pineapple juice rate of the machine is high.

- Maximum preservation of pineapple's flavor and nutrients.

- We can configure the machine to meet the different requirements for the production of all pineapple products, such as pineapple pulp, pineapple juice, pineapple canned products.

- The production line has a high degree of automation, efficient and safe operation.

-lp.jpg)