What is AGICO Industrial Freeze Dryer?

A freeze dryer, scientifically known as a vacuum freeze dryer, is an advanced piece of equipment that removes moisture from materials through the principle of sublimation under low-temperature and vacuum conditions. "Sublimation" refers to the process where water transitions directly from its solid state (ice) to its gaseous state (water vapor), bypassing the liquid phase.

The freeze-drying process primarily consists of three stages:

- Freezing Stage: The material is rapidly cooled below its eutectic point, completely freezing the internal moisture into solid ice crystals, laying the foundation for subsequent sublimation.

- Primary Drying (Sublimation Drying): Under a vacuum, a small amount of heat is supplied to the system, causing the ice crystals within the material to sublime directly into water vapor. This stage removes approximately 90% or more of the material's moisture.

- Secondary Drying (Desorption Drying): At a higher vacuum and temperature, residual moisture physically bound to the material's matrix is removed through molecular desorption, ultimately achieving a very low final moisture content.

Through this non-thermally destructive process, freeze-drying technology maximally preserves the original physical, chemical, and biological properties of the material, including its shape, color, nutritional components, bioactivity, and flavor compounds. Simultaneously, it grants the product an exceptionally long shelf life and offers excellent rehydration, making it the ideal technology for producing high-end, high-value-added products.

Core Components of Industrial Freeze Drying Systems

An industrial freeze dryer is a complex system engineering project, primarily composed of the following core systems:

Overhead rail transport system

Function: To swiftly transport products between key areas, saving labor and time.

Design: AGICO's system uses sliding trolleys on an overhead rail to connect the freezing room, drying chamber, and pallet stations in a continuous process.

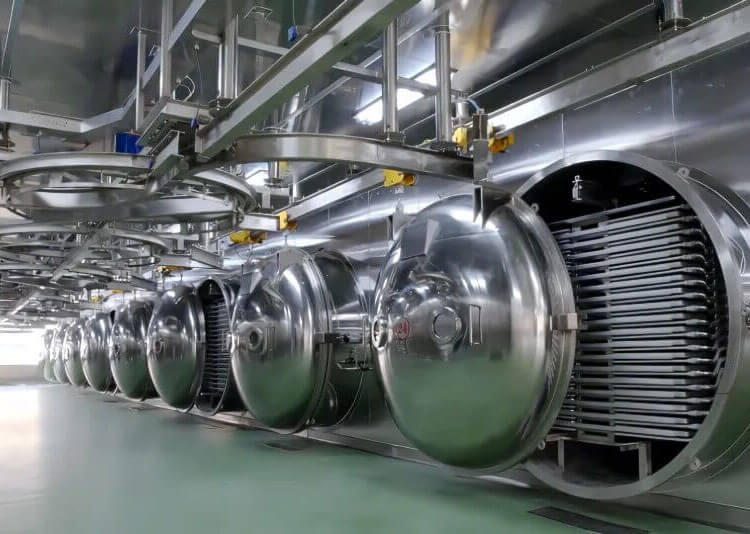

Drying Chamber System:

Function: The core cavity that houses the material where drying occurs.

AGICO Design: Constructed from high-quality SUS304 or 316L stainless steel, with internal mirror polishing (Ra value <0.6µm), ensuring no sanitary dead ends and compliance with cGMP and FDA hygiene standards. The chamber is designed with a large sight glass and ports for process validation.

Heating System:

Function: Provides precise and uniform heat for the sublimation process.

Refrigeration System:

Function: Used for pre-freezing the material and providing low temperatures for the condenser to capture water vapor.

AGICO Design: Employs high-efficiency semi-hermetic piston compressors or screw compressors with strong cooling capacity and rapid cooldown, capable of reaching -40°C from room temperature in ≤60 minutes. Using eco-friendly refrigerants, it ensures condenser temperatures as low as -55°C or even -80°C.

Vacuum System:

Function: Creates and maintains the low-pressure environment required for sublimation.

AGICO Design: Consists of an efficient vacuum pump group, such as Roots pumps, rotary vane pumps, or dry pumps, capable of rapidly achieving and maintaining a high vacuum (ultimate vacuum ≤5 Pa). The system is equipped with condenser-isolation valves, vacuum regulation valves, etc., effectively protecting the vacuum pump and precisely controlling the sublimation process.

Control System:

Function: The "brain" of the entire equipment, responsible for coordinating all systems, executing, and recording the entire freeze-drying process.

AGICO Design: Uses internationally renowned brand PLCs (e.g., Siemens/OMRON) + large industrial touchscreen HMI. The system features recipe management, user access control, real-time curve display, data recording, and export functions, fully compliant with FDA 21 CFR Part 11 regulations for electronic records and electronic signatures.

Get Price Now

Get Price Now

Features of AGICO Industrial Food Freeze Dryer Machine

- Exceptional Drying Quality: Perfectly preserves the material's shape, color, and over 95% of its nutritional components, with excellent and rapid rehydration, restoring quality close to its original state.

- Efficient Industrial Design: Available in integrated (chamber & condenser) or split-type designs to suit different factory layouts. High-efficiency refrigeration and vacuum systems significantly shorten the freeze-drying cycle and increase production capacity.

- Comprehensive Intelligent Control: Fully automated PLC control supports recipe management, remote monitoring, and data traceability, enabling intelligent and repeatable production.

- Robust & Sanitary Construction: Constructed entirely of stainless steel with mirror polishing. All pipeline connections use sanitary clamps for easy cleaning and sterilization, meeting the highest hygiene standards.

- Complete Safety Protection: The system integrates multiple safety interlocks, including over-temperature, over-pressure, overload, and power-off recovery protection, ensuring the safety of both the equipment and the product.

Available Models

| Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| FZG-5 | FZG-10 | FZG-20 | FZG-30 | FZG-50 | FZG-100 | FZG-150 | FZG-200 | FZG-300 | |

| Effective Area (m²) | 5 | 10.5 | 20 | 30.1 | 50.31 | 98.68 | 148 | 197.4 | 296 |

| Shelf Size (L*W*H) (cm) | 100*100*2 | 150*100*2 | 200*100*1.5 | 214*54*1.8 | 310*54*1.8 | 608*54*1.8 | 912*54*1.8 | 1216*54*1.8 | 912*54*1.8 |

| Number of Shelves(PCS) | 5+1 | 7+1 | 10+1 | (13+1)*2 | (15+1)*2 | (15+1)*2 | (15+1)*2 | (15+1)*2 | (15+1)*2*2 |

| Shelf Spacing(mm) | 65 | 65 | 70 | 77 | 77 | 77 | 77 | 77 | 77 |

| Number of Carts (SUS304)(PCS) | / | / | / | 1 | 2 | 4 | 6 | 8 | 12 |

| Ice Condensing Capacity(KG) | 100 | 200 | 400 | 600 | 800 | 1500 | 2000 | 3000 | 4500 |

| Shelf Temperature Range(°C) | -45 ~ +80 | ||||||||

| Condenser Temperature(°C) | ≤ -65 | ||||||||

| Chamber Vacuum Degree(Pa) | ≤ 2.7 | ||||||||

| Electric Heating (Option)(KW) | 9 | 16 | 24 | 12*3 | 16*3 | 24*4 | 48*3 | 32*6 | 48*6 |

| Installed Power(KW) | 40 | 63 | 90 | 125 | 150 | 290 | 380 | 570 | 750 |

| Unit Dimensions (L*W*H)(M) | 4.5*2.1*3.6 | 6.3*2.1*3.6 | 7.6*2.1*3.6 | 7*2.5*3.6 | 9.1*2.5*3.6 | 15.7*2.5*3.6 | 25*2.5*3.6 | 29*2.5*3.6 | 50*2.5*3.6 |

| Weight(T) | 5 | 6.5 | 7.5 | 10 | 13.5 | 20 | 30 | 36 | 60 |

*The above data is for reference only. Customization is available according to user requirements. Final data is subject to the terms of the contract.

Contact us for product catalogApplication of Freeze Dryer Machine

AGICO industrial freeze dryers serve numerous high-tech and demanding industries with their exceptional performance:

Food Industry:

- High-End Fruits & Vegetables: Strawberries, durian, mushrooms, chives, instant soup ingredients, creating premium snack foods.

- Health Beverages: Instant coffee, tea powder, fruit and vegetable powders, preserving natural flavor and nutrition.

- Protein Products: Beef, shrimp, probiotics, yogurt starter cultures.

- Seasonings & Pet Food: Natural seasoning powders, high-quality pet fresh food.

Pharmaceutical & Biotechnology:

- APIs & Formulations: Freeze-drying of thermolabile pharmaceuticals like antibiotics and hormones.

- Biological Products: Long-term preservation of vaccines, serum, proteins, enzymes, cells, and tissues while maintaining activity.

Health Products & Traditional Chinese Medicine (TCM):

- Precious Chinese Herbs: Ginseng, Dendrobium, Cordyceps, Ganoderma, maximizing the retention of medicinal components.

Scientific Research & New Materials:

- R&D: Used by universities and research institutes for process development.

- New Materials: Preparation of nanomaterials, ceramic powders, microencapsulated products.

Get Price Now

Get Price Now

Advantages of Our Products & AGICO

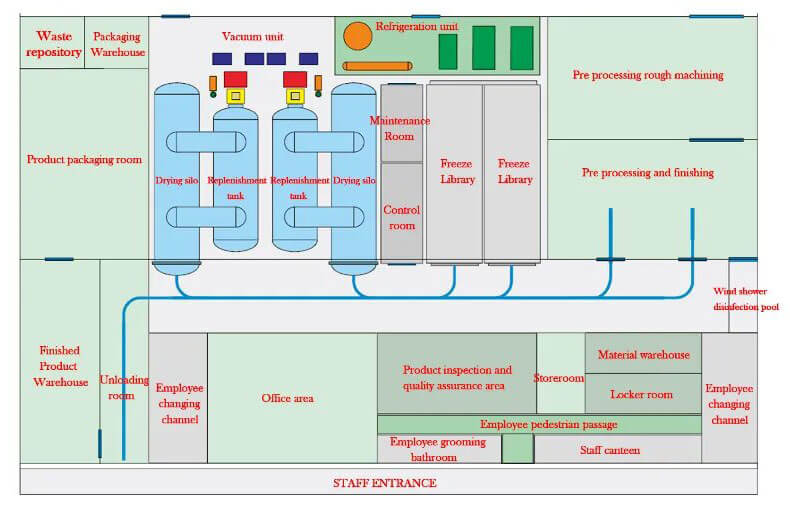

Deep Customization Solutions

We understand that standardized products cannot meet all needs. AGICO provides end-to-end customization services—from factory layout design and core component selection (compressors, vacuum pumps) to control system configuration—ensuring the equipment perfectly matches your process and capacity requirements.

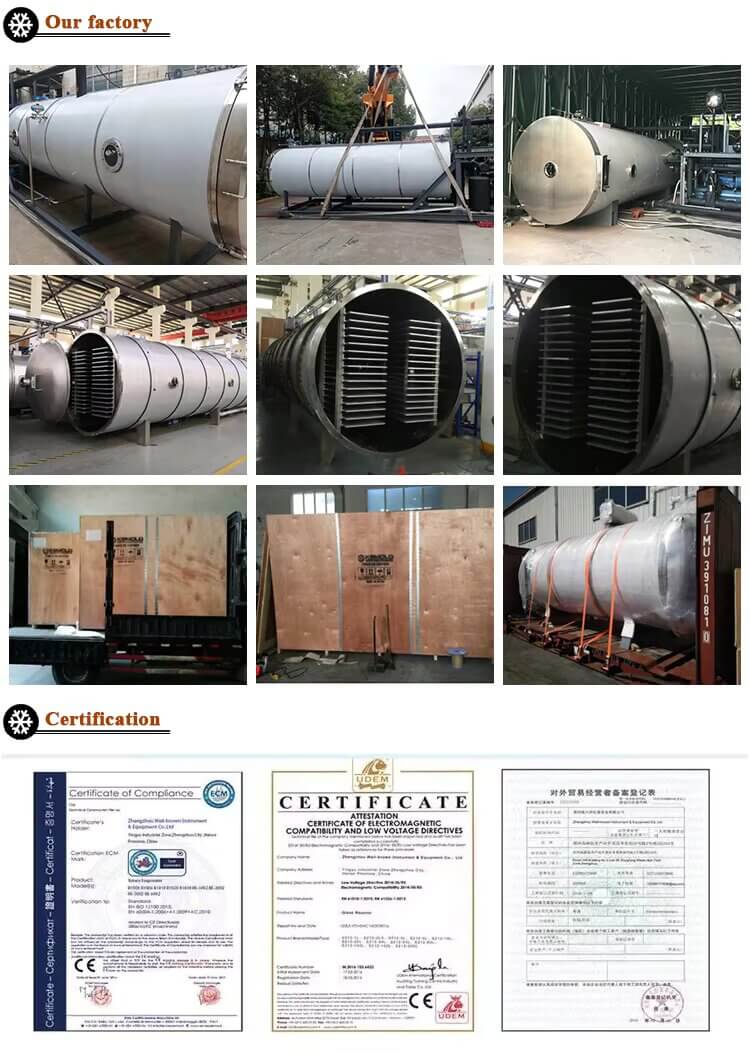

Industrial-Grade Reliability & Durability

From steel plates to core components, we insist on using renowned domestic and international brands. Rigorous manufacturing processes and strict factory testing ensure that every AGICO freeze dryer can withstand the harsh challenges of 7x24 continuous stable operation, providing you with long-term return on investment.

Forward-Looking Intelligent Control & Compliance

Our control systems are not only highly automated but are also designed with compliance to FDA 21 CFR Part 11 requirements built-in from the start, clearing obstacles for your entry into international high-end markets, especially the pharmaceutical sector.

Lifecycle Partnership

AGICO sells not just equipment, but a commitment. We provide comprehensive lifecycle services including installation & commissioning, operational training, preventive maintenance plans, global spare parts supply, and rapid response support, positioning ourselves as your trustworthy long-term technical partner.

-lp.jpg)