AGICO Commercial Freeze Dryer

Get a free quote

Get a free quote

In industrial and scientific fields, which pursue efficiency, health, and high value, achieving long-term, stable preservation without damaging the core structure and active components of materials is a critical challenge. Drawing on our profound expertise in industrial equipment manufacturing and innovative spirit, AGICO offers you a cutting-edge solution – the AGICO Commercial Freeze Dryer.

Freeze-drying, also known as lyophilization, is a process in which water-containing materials are frozen at low temperatures and then placed under a high vacuum, allowing the ice crystals within to sublimate directly into vapor and be removed. The AGICO Commercial Freeze Dryer is a perfect example of this engineering principle in application. It is not merely a piece of equipment but a precision preservation system capable of maximally retaining the original physical structure, biological activity, color, and flavor of the material, allowing it to quickly return to its fresh, pre-dried state upon rehydration. Whether for food companies seeking natural and healthy products, pharmaceutical companies ensuring drug activity, or cultural institutions restoring precious artifacts, the AGICO Freeze Dryer is your trusted partner.

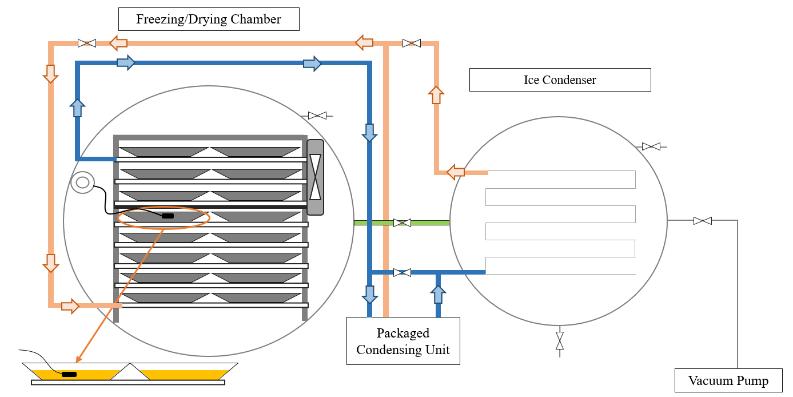

Components & Operation of Commercial Freeze Dryer

Structure of freeze dryer

AGICO freeze dryers are built with robust, precision-engineered subsystems that work in seamless harmony:

Product Handling System

Wheeled carts constructed from 304 stainless steel facilitate easy and hygienic product transport. The product trays, the sole contact surface, are made from certified food-grade materials. This design minimizes cleaning requirements, drastically reduces the risk of cross-contamination, and ensures a simple, flexible workflow.

Shelf and trolley

Drying & Sublimation System

The core sublimation process is fully automated for each batch. Operation is straightforward: simply load the product, close the heavy-duty drying chamber door, set the parameters, and initiate the cycle. This automation guarantees ease of use and consistent, repeatable results batch after batch.

Heat Supply System

The system provides precise temperature control across a wide range, from ambient room temperature up to 90°C. This ensures optimal heat transfer during the sublimation phase, crucial for preserving product integrity, bioactivity, and quality.

Drying chamber

Vacuum System

A high-performance vacuum system rapidly evacuates the drying chamber, typically achieving the required process vacuum levels within 10-12 minutes. For products with specialized requirements, this time can be even shorter, enhancing overall cycle efficiency.

Refrigeration System

Equipped with industrial-grade compressors, the system ensures highly efficient and reliable cooling. For multi-unit installations, condensers can be configured to share a common refrigeration system, enabling staggered operation for significant energy savings and reduced operational consumption.

De-icing System

The batch-type water-flush de-icing system efficiently removes ice from the condenser during the natural interval between drying cycles. This process is typically completed in about 30 minutes without impinging on production time, offering a low-cost and easy-to-operate solution.

Control System

At the heart of the system is an advanced PLC-based industrial controller with an intuitive touch-screen interface. It supports manual/automatic operation, provides real-time control and monitoring of all parameters, and features data logging with process curve printing capabilities. This intelligent system orchestrates the freezing, drying, heating, vacuum, and refrigeration subsystems to work efficiently in concert, ensuring the machine always operates at peak performance.

Standard Features

Structure:

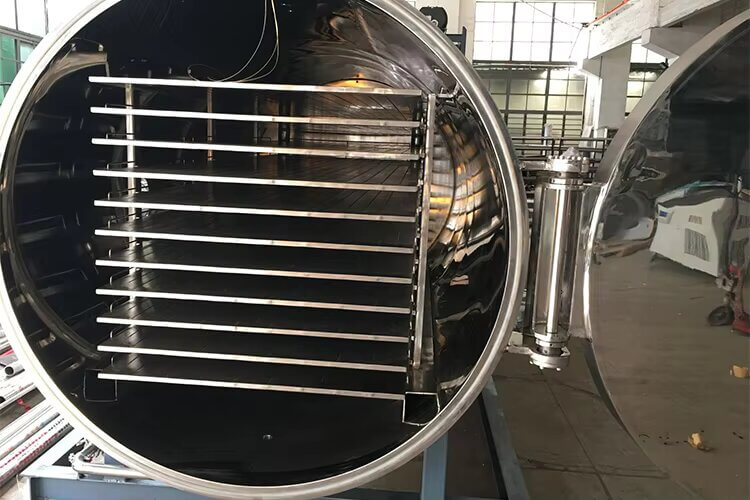

- Hygienic Construction: The drying chamber and product contact parts are made of 304 stainless steel and food-grade materials, meeting the highest sanitary standards.

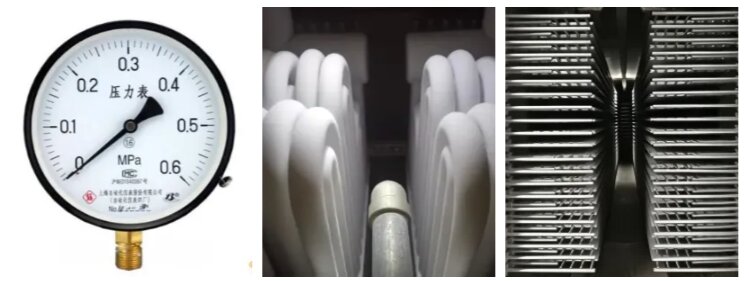

- Efficient Heat Transfer: Shelves and trays are crafted from anodized aluminum alloy, optimizing thermal conduction for reduced power consumption.

- Uniform Heating: Shelves employ a double-sided radiant heating design with distilled water as the safe, non-toxic heat transfer medium, ensuring even product drying and eliminating contamination risks even in the event of a leak.

- Contamination Prevention: The condenser is strategically installed within the chamber with a clear separation between dry and wet areas, preventing any risk of product contamination during operation.

- Cylindrical Chamber: Features a single-door design with a integrated observation window for process monitoring.

Performance:

- Shelf Temperature Range: Ambient to 90°C

- Shelf Heating Rate: 1~2°C/min

- Ultimate Condenser Temperature: -40°C

- Condenser Cooling Time (to -30°C): < 30 minutes

- Maximum Drying Chamber Vacuum: < 4 Pa

- Vacuum Pump-down Time (Atm to 133 Pa, empty): < 12 minutes

Advantages

Compact & Economic Design:

Our plug-and-play compact design, with all subsystems centralized on a single steel frame, enables easy transportation, quick installation, and a small footprint, saving valuable floor space and accelerating your time from order to production.

The use of standardized wheeled carts and a rationalized structure ensures a low initial investment cost.

Unmatched Economic Benefits:

The lyophilization process creates a stable product with a dramatically extended shelf life.

Freeze-dried products remain stable at ambient temperatures, eliminating the need for expensive cold chain logistics.

Significant weight reduction of the final product leads to substantially lower transportation and handling costs.

Operational & Efficiency Advantages:

Engineered for low power consumption and high sublimation rates.

Simple, reliable operation with precise control over temperature and vacuum.

Negligible power loss and remote monitoring/control capabilities.

Freeze-drying recipes are fully programmable, storable, and modifiable.

Easy to clean and maintain, with all major components and valves controllable via the PLC.

Applications

AGICO freeze-drying technology is deeply empowering numerous industries, creating limitless possibilities:

- Food Industry: Nutrient lock-in and quality enhancement for high-end fruits & vegetables, instant beverages, seasonings, instant soup bases, seafood, meats, pet food, and treats.

- Pharmaceutical & Biotech: Drying and stabilization of antibiotics, vaccines, blood products, hormones, herbal extracts, probiotics, and various diagnostic reagents.

- Research & Academia: Provides a reliable freeze-drying platform for experimental research in life sciences, materials science, archaeology, and more.

- Chemicals & Materials: Preparation of catalysts, nanomaterials, ceramic powders, and fine chemical intermediates.

- Cultural Heritage Preservation: Used for the dehydration, setting, and conservation of water-damaged ancient books and precious artifacts.

Customized Freeze-Drying Solutions

AGICO offers extensive customization services. We can adjust the drying chamber size, shelf spacing, condenser capacity, and installation method to your specific requirements. Our collaborative approach combines your industry expertise with our technical prowess to jointly design and manufacture a commercial freeze dryer that delivers a distinct competitive advantage for your business.

Embrace the future of preservation with AGICO. Let us provide you with the technology and support to enhance your product value and operational efficiency.

-lp.jpg)