Bottle Unscrambler Introduction

Bottle unscramber is the soft beverage ancillary equipment, which is design for high speed filling line. It can perform the process from feeding disordered PET to air conveyor of the filling machine in sequence to meet automatic production requirement of filling machine.

Bottle Unscrambler Features

- The bottle blocking tester will give an alarm when the bottle is blocked.

- It is equipped with bottle eliminating mechanism.

- Adopt bottle mouth air channel so that the bottle can’t be turned over during transportation.

- Controlled by PLC procedure, digital readout of unscrambling bottle speed.

- Storage tank of high-capacity, which can avoid starving.

- Easy to operate, clean and maintain.

- The photoelectric switch is installed on the air conveyor to control the unscrambled machine.

- Run automatically at high speed, easy to combine with all kinds of fillers or filling production lines.

- Bottle unscramble machine has oil mouths which make the gear, bearing, and cam lubrication convenient.

- The no-bottle detector will send a signal to the elevator immediately when the bottle quantity is few and the elevator shall supply bottles automatically.

-

The direction of bottle lifting can be various.

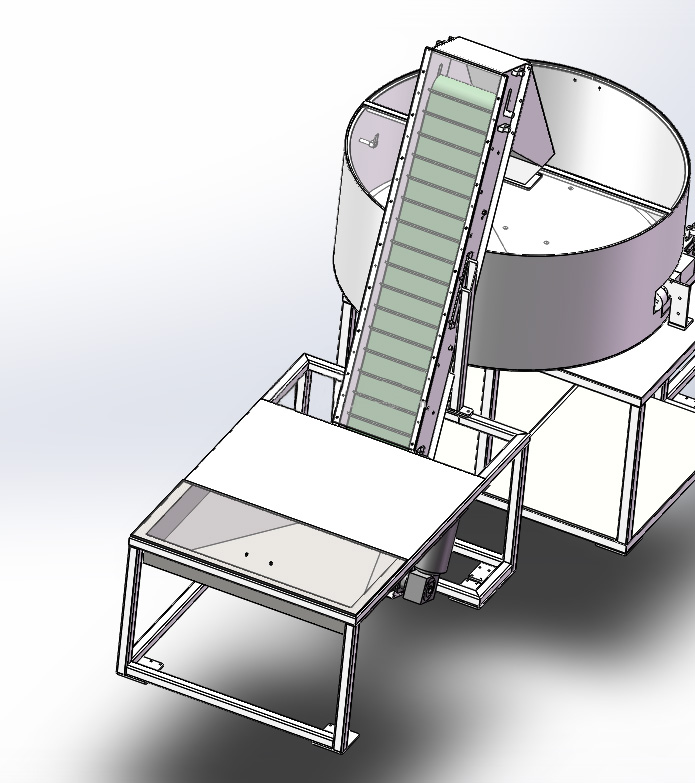

The Structure and Working Principle of the Bottle Unscrambler

The appearance of main engine is cylindrical, and the bottom of the outer cylinder is equipped with adjustable feet for adjusting the height and level of the machine. There is a rotating cylinder in the cylinder, the outside of the rotating cylinder is equipped with a bottle drop groove, and the inside is equipped with a lifting mechanism equal to the number of bottle drop grooves. The machine is equipped with a fixed umbrella-type tower. When the hoist signals the lack of bottles according to the bottle detection device set on the umbrella-type tower, the bottles fall on the umbrella-type tower from the top of the machine and slide to the edge of the umbrella-type tower to enter the lifting mechanism.

The lifting mechanism pushes the bottle into the bottle drop groove under the action of the cam. After the bottle is sorted in the bottle drop groove, it rotates with the bottle drop groove to the bottle outlet of the bottle unscrambler machine. Then the bottles will be sent out through planet wheel into air conveyor. The planet wheel is connected to the motor's main axis by a synchronous belt.

Application of the Bottle Unscrambler

It is used for different shapes and materials bottles and containers (round, square, etc.) It is widely used in pharmaceutical fields, healthcare products fields, foods, etc.

|

|

Bottle Unscrambler Technical parameters

| Model | Capacity(bph) | Compressed of air Pressure(Mpa) | Gas volume(m3/min) | Power(kw) | To adapt to bottle-type(mm) | Dimensions(mm) |

|---|---|---|---|---|---|---|

| ABU-1 | 8000-12000 | 0.7 | 0.5 | 2.2 |

Bottle Drive 50-90, bottles of high 150-290 |

2500*2660*2000 |

| ABU-2 | 1200-1800 | 0.7 | 0.6 | 4.4 | 2650*3300*2200 |

Packing and Delivery

-lp.jpg)