Colloid Mill Machine Application

This machine is suitable for pharmaceutical, foodstuff, chemical and other industries of wet superfine grinding materials, and can play all kinds of half wet body and emulsion material crushing, emulsion, homogeneous, and mixing. In the field of foodstuff, colloid mill machine is applicable to processing fruit tea, ice cream, cream, jam, fruit juice, soybean, bean paste, red bean milk, peanut milk, protein, soy milk, dairy products, malted milk, essence and various beverages.

Colloid Mill Machine Working Principle

Through high speed relative motion of rotor and stator, make the material get strong shearing force, friction and high mode vibration. Effectively crush, emulsify, homogeneity material to reach refined product. The crushing space is equipped with two grinding zones, the first stage is the fine grinding area, the second level is the ultra-fine grinding area, and the crushing fineness can be adjusted. The gap between the upper and lower copper grinding discs can effectively achieve the required ultra-fine crushing effect at one time.

Colloid Mill Machine Features

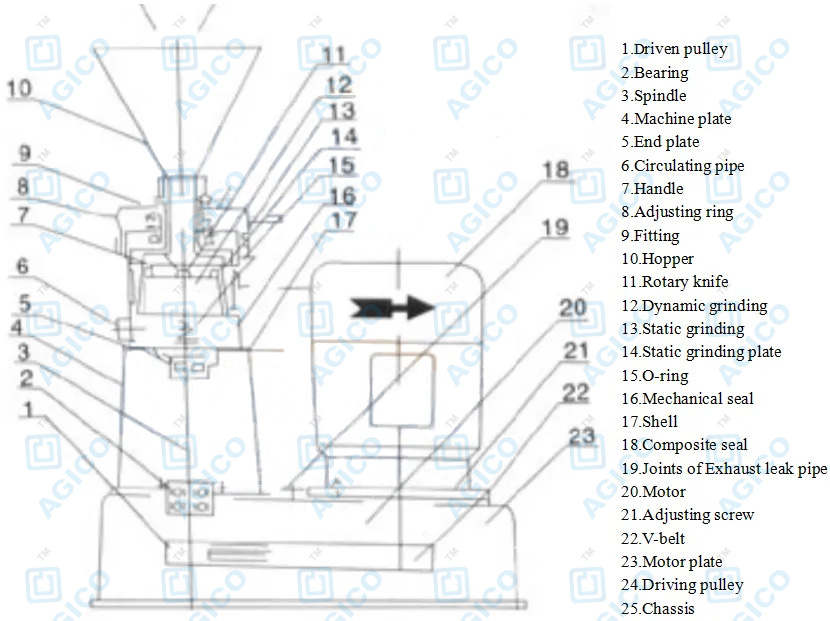

- The colloid mill is mainly composed of motor, grinding head, transmission base, spinning rotor and fixed stator etc.

- Parts contacting materials are made of stainless steel, corrosion-resistant and durable for use.

- Low noise and small occupancy space, saving energy and cost.

Colloid Mill Machine Notice

- It’s never allowed to be mixed with hard materials such as quartz sand, broken glass, scrap metal, and strictly prohibited into the processing equipment.

- Make sure that the chamber of the machine must have water or liquid materials when started or closed machine and before and after washing machine, barred idling and reverse. Otherwise, improper operation may damage mechanical components or causes motor spilling and burning faults.

| Model | Capacity(kg/h) | Power(kw) | Weight(kg) | Dimension(mm) |

|---|---|---|---|---|

| JM-50 | 10-15 | 1.1(380V)1.5(220V) | 50 | 530*260*580 |

| JM-80 | 70-150 | 4(380V) | 150 | 640*410*580 |

| JM-110 | 200-300 | 15(380V) | 175 | 700*430*980 |

| JM-130 | 400-600 | 15(380V) | 285 | 830*440*1100 |

| JM-180 | 800-1000 | 18.5(380) | 340 | 830*490*1100 |

Details of Colloid Mill Machine

Installation and Use of The Colloid Mill Machine

- The equipment is installed horizontally on a flat concrete foundation and fixed with anchor screws (depending on the working situation, it can also be unfixed).

- Check that each fastening screw is tightened.

- Before use, use a special wrench to rotate the rotor, and check whether it is in contact with the stator, and whether there is jamming, if there are the above conditions, it is not allowed to start.

- Connect the power supply and check that the rotor rotation direction is consistent with the arrow on the base (clockwise).

- Turn on the cooling water and pay attention to the water inlet and outlet signs of the water nozzle.

- When starting the motor, first press the switch to check whether there is any noise or vibration. If the situation is abnormal, it should be stopped immediately and then restarted after troubleshooting.

- After work, cleaning the residual materials in the stator and rotor should be carried out in the running state, and the large chuck should be rotated counterclockwise for not less than 90° before cleaning.

Packing and Delivery

-lp.jpg)