Different from ordinary citrus juice processing line, this special citrus juice processing line adds the function of citrus oil extracting, and this step is not affect the following processing of citrus juice. Citrus essential oil is an important food additives, and also widely applicable in chemical industry, pharmaceutical industry and etc.

The orange juice processing machine is the main equipment in this production line which is responsible for extracting the pulp and juice from the fruits.

We can design and manufacture whole line of citrus juice production line according to your requirement. The capacity of citrus juice processing line can be 5T-15T/H. Products types can be of 1 or 2 or more kinds. Just like making orange juice, lemon juice, grapefruit juice, lime juice and pomelo juice, etc.

|

|

|

|

|

| Orange Juice | Lemon Juice | Grapefruit Juice | Lime Juice | Pomelo Juice |

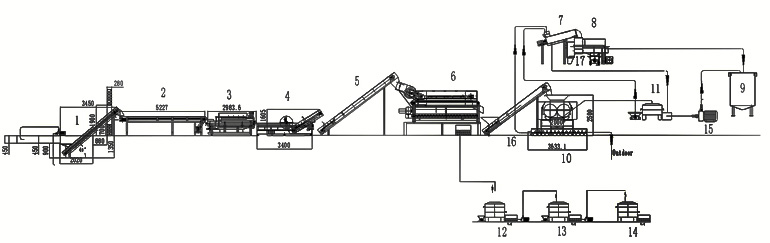

The processing line is mainly composed of the following phases

1. Fruit elevator 2. Fruit sorter 3. Brush and spray cleaning machine 4. Fruit bubble washing machine 5. Fruit elevator 6. Citrus fruits peel essential oil extractor 7. Juice separator 8. Citrus pulper 9. Storage tank 10. Peeling and squeezing machine 11. Sieving machine 12. Sieving machine Ⅱ 13. Sieving machine Ⅲ 14. Sieving machine Ⅳ 15. Pump Ⅰ 16. PumpⅡ 17. Pump Ⅲ

The flowchart is the processing line of the citrus juice. The process of orange juice production is first orange was washed by using washing machine, and then the bad ones are picked out, to make sure that the fruits to be processed are all of good quality. Those good ones are extracted and pulped.

Fruit washing --- Fruit elevator---Fruit sorter--- Brush type citrus cleaning--- Fruit bubble washing--- Citrus oil extracting(Separate oil from water)---Citrus peeling and squeezing--- Fruit pulping ---Storage

Crushing before juicing can improve the juice yield, but the crushing rate should be moderate, otherwise excessive crushing is easy to cause the outer pulp to be squeezed out quickly during pressing, and then form a thick skin, making it difficult for the inner juice to flow out, resulting in a decrease in juice yield.

End products:

|

.jpg) |

.jpg) |

Main Equipment of The Citrus Juice Concentrate

Be used in the low or high level lifting and conveying of fruit and vegetables.The bucket elevator adopts 304 stainless steel plate to convey and lift fruit and vegetables, and the materials are intermittently transported to the next station for further processing, which solves the accumulation and blocking problems caused by the belt conveyor.Bucket elevators are often used in the food processing industry, especially for the handling and transportation of fragile fruits and vegetables. They are widely used in processing plants and farms, this ensures that fruit are transported gently and efficiently, and reduces the risk of spoilage of fruit and vegetables.

Compared with scraper elevator and belt conveyors, bucket elevators occupy less plant area and can make the entire transportation system very compact.

| No. | Equipment name | Picture |

|---|---|---|

| 1 | Elevator | |

| 2 | Rolling rail fruit sorting machine | |

| 3 | Brush and spray cleaning machine |

|

| 4 | Fruit bubble washing machine | |

| 5 | Citrus fruits peel essential oil extractor | |

| 6 | Peeling and squeezing machine | |

| 7 | Sieving machine Ⅰ |

|

| 8 | Citrus pulper |

1. Elevator

The bucket elevator adopts 304 stainless steel plate to convey and lift fruit and vegetables, and the materials are intermittently transported to the next station for further processing, which solves the accumulation and blocking problems caused by the belt conveyor.

Bucket elevators are often used in the food processing industry, especially for the handling and transportation of fragile fruits and vegetables. They are widely used in processing plants and farms, this ensures that fruit are transported gently and efficiently, and reduces the risk of spoilage of fruit and vegetables.

Compared with scraper elevator and belt conveyors, bucket elevators occupy less plant area and can make the entire transportation system very compact.

2. Rolling rail fruit sorting machine

Sorting of citrus fruit by manual. This rolling rail fruit sorting machine is suitable for sorting spherical or oval fruit and vegetables such as oranges, mangoes, tomatoes, etc. It consists of frames, reducers, rollers, and other components. After the fruit enter the machine, under the influence of gravity, they are paved on the surface of the rollers in a single layer by themselves. Unqualified fruit and vegetables are manually sorted during transportation to ensure the quality of fruit and vegetables.

3. Brush and spray cleaning machine

Removing of extraneous matters and eliminating the stickiness contained on most of the citrus peels.Brush and spray cleaning machine is used to clean spherical and slender fruit and vegetables, which has great benefits for the factory to save labor, improve production efficiency and reduce production costs.

Removing of extraneous matters and eliminating the stickiness contained on most of the citrus peels.Brush and spray cleaning machine is used to clean spherical and slender fruit and vegetables, which has great benefits for the factory to save labor, improve production efficiency and reduce production costs.This equipment is mainly composed of frame, main drive, passive drive, brush roller, geared motor, spray device, feed hopper, discharge hopper, etc. The brush is made of high-quality nylon. The brush roller and frame are made of SUS304 material, which fully meets the requirements of export food hygiene. Depending on the working conditions, the hardness of the brush rollers can be changed. The washed fruit enters the brush and spray cleaning machine, and the fruit and the brush roller rub against the fruit to remove the remaining leaves and soil on the surface of the fruit and vegetables. The spray device on the top can clean up the removed debris, multiple groups of brush rollers run at the same time, and the fruit drive device conveys the fruit and vegetables to the discharge hopper and then enters the next process.

4. Fruit bubble washing machine

Washing fresh vegetables and fruits. The fruit bubble washing machine is mainly composed of two parts: one water bubbling tank and one elevator, which are mainly used for cleaning fruit and vegetables. The equipment is equipped with a bubble generator that rolls the fruit and vegetables and removes dirt from their surface. Bubble cleaning machine is widely used in cleaning and soaking of various fruit and vegetables and other agricultural products. The whole machine is frequency controlled, and the washing capacity is adjusted. Compared with other products, it has the characteristics of stable operation and long service life.

Washing fresh vegetables and fruits. The fruit bubble washing machine is mainly composed of two parts: one water bubbling tank and one elevator, which are mainly used for cleaning fruit and vegetables. The equipment is equipped with a bubble generator that rolls the fruit and vegetables and removes dirt from their surface. Bubble cleaning machine is widely used in cleaning and soaking of various fruit and vegetables and other agricultural products. The whole machine is frequency controlled, and the washing capacity is adjusted. Compared with other products, it has the characteristics of stable operation and long service life.5. Citrus fruits peel essential oil extractor

Special equipment for extracting essential oil from citrus’s peel. One of the most important by-products in the processing of citrus juice is citrus oil. It can be extracted from citrus peels. Citrus oil has a wide range of applications in the food and cosmetics industry.

Special equipment for extracting essential oil from citrus’s peel. One of the most important by-products in the processing of citrus juice is citrus oil. It can be extracted from citrus peels. Citrus oil has a wide range of applications in the food and cosmetics industry.We specialize in designing and developing citrus oil extractors to obtain citrus oil. It can extract oil from oranges, grapefruit, lemons, limes. It is mainly composed of stainless steel gears, gear shafts, spiral, grinding roller, inlet and outlet hopper, spray pipe, oil collection tank.

6. Peeling and squeezing machine

Remove the peel out of citrus, and extract the juice on the first time. It is designed according to the characters of lemon, so it is a very ideal equipment for citrus juicing. The equipment is suitable for peeling and juicing citrus, bananas, pineapples, passion fruits, etc.

Remove the peel out of citrus, and extract the juice on the first time. It is designed according to the characters of lemon, so it is a very ideal equipment for citrus juicing. The equipment is suitable for peeling and juicing citrus, bananas, pineapples, passion fruits, etc. 7. Sieving machine Ⅰ

Separating oil from water.

Separating oil from water.Features:

1.Screen mesh without blocked, the powder does not fly.

2. It is easy to change mesh, to operate, and to clean;

3. Discharged automatically, can automate operations;

4. Small volume, light weight, can use full space, easy to move;

5. High efficiency in screening and filtration, applied for any granule, powder, mucus;

6. Unique frame structure design, screen can be use long time;

7. High efficiency, compact and durable design, any powder and mucus are applicable.

8. Citrus pulper

Destoning and pulping of the citrus. The fruit pulping machine is the equipment that beats the broken fruit or the whole fruit into a pulp through the crushing blade and rotor paddle mechanism.

Destoning and pulping of the citrus. The fruit pulping machine is the equipment that beats the broken fruit or the whole fruit into a pulp through the crushing blade and rotor paddle mechanism.The Pulp machine has a wide range of applicability. The fruit pulping machine is composed of broken blades, propellers, rotor paddle, screens sieves, gripper, frame, transmission system, pulp collecting tank and other components.

The main factors affecting the fruit pulping rate are related to the characteristics of the fruit itself, the speed of the pulping machine shaft, the diameter of the screen, the size of the angle, and the temperature of the fruit pulp.

Citrus Oil Processing Line

The remaining citrus peel from the citrus can also be made into citrus oil. Though unknown to most people, citrus oils are a significant industry to themselves. Higher quality oil is more valuable because it contains more flavor and aroma components. Usually this oil is not heat treated and has very little contact with fruit and water. Worldwide fragrance and flavoring companies purchase premium oils for further refining.

The citrus oil recovery system process includes citrus oil extraction, citrus oil refining, two-stage separating and essential oil de-waxing.

Citrus oil extracting → Citrus oil refining → Primary centrifugal separating → second-stage polishing centrifuge → Essential citrus oil de-waxing → Essential citrus oil storage

.jpg)

Main Features of the citrus processing line:

- With advanced technology from German and Italy.

- High efficiency and large output without classification.

- No two-step processing is required.

- The parts contacting with raw materials directly are made of stainless steel 304.

- Being suitable for large-scale industrial production.

- The floor area of the workshop is approximately 30m multiply by 5m. And the power consumption is about 105kw.

.jpg)

-lp.jpg)