What are the steps in mango juice making?

The mango juice making process covers sorting, peeling and destoning, softening, pulping, homogenization, degassing, sterilization, filling and packing, and cooling.

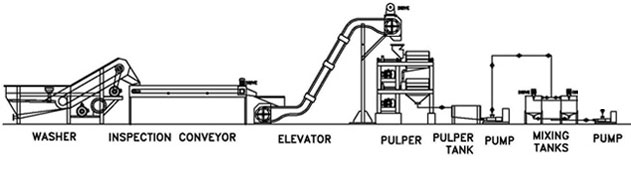

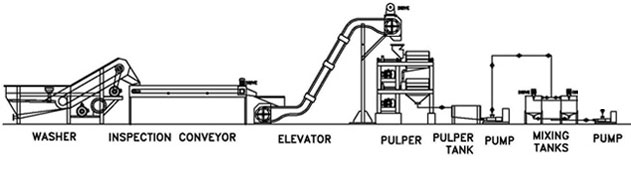

A

mango juice processing line includes the following equipment, but not all the equipment is indispensable.

-

Fruit sorting machine

-

Fruit washing machine

-

Mango pulper machine

-

Vacuum degasser

-

Juice homogenizer

-

Juice pasteurizer

-

Juice filling machine

Mango juice processing steps 1: sorting and washing

Clean the selected mangoes one by one. During the picking process, the outer surface of the mango is easily mixed with the juice and soil of other mangoes. These are all dirt. Before pulping or squeezing, you need to ensure that the original fruit is clean to ensure that the mango is safe. Food safety during production. The equipment used to clean mango juice can use a flat-bed spray cleaning machine. Manually and gently pour the mangoes onto the flat-bed conveyor, and use the clean water from the spray to clean the mangoes. You can also use a bubble cleaning machine to clean the surface of the mangoes. Rinse and beat the cleaned mango directly to the next step.

Mango juice processing steps 2: peeling and pulping

Before squeezing mango juice, be sure to warm it up. This can soften the pulp tissue and increase the mango juice yield. Differences in heating temperature can promote or prevent enzyme activity. Depending on the properties of the enzyme, we need to master the appropriate pH value, temperature, and action time.

The mango pulper machine integrates the function of mango peeling, destoning, and pulping. As a specialized mango juice processing machine, it can remove the core and peel of mango completely and reduce the loss of mango pulp as much as possible. The pulp recovery rate is up to 99.5%. The production capacity is from 5t/h to 20t/h.

Mango juice processing steps 3: blending

The concentration of the puree is generally relatively high. The conventional method requires drinking water for blending. Add a large amount of water, add sugar, and essence. These are added in the front to dilute the taste of the mango drink, and then add preservatives and stabilizers. , Stabilize the shelf life of the drink. The stabilizer makes the mango drink particles more evenly suspended. White sugar is difficult to dissolve in the normal state. It can be quickly dissolved by using a steaming sugar pot and electric stirring. For the preparation of mango juice, use a jar and use high-speed stirring. The stirring, sugar pan, and mixing tank are made of 304 stainless steel sanitary storage tanks. The prepared beverage is filtered clean by double filtration, and then the particles of the beverage are cut into finer particles through a high-pressure homogenizer to better suspend them in the mango beverage. A vacuum degasser is used to remove the air in the beverage to extend the shelf life. It prevents browning and deterioration. Such a system for the production of mango juice drinks is called a mango juice drink blending system.

Mango juice processing steps 4: sterilization

Mango beverages need to undergo warm sterilization before filling. Such sterilization equipment is called a UHT sterilizer. Depending on the type and requirements of the material, UHT has a variety of configuration options, which can be further divided into: "plate sterilizer", and "tube sterilizer" Sterilizer" two types. Tubular sterilizers are used to sterilize various types of beverages, but the equipment prices are relatively high.

Mango juice processing steps 5: filling and packing

The mango beverage produced uses the conventional filling method using high temperature. Different equipment is selected according to the type of bottle. The rinse clamp for plastic bottles uses the bottle clamping type, while the glass bottle uses the bottle clamping type on both sides. The structure is still the same. The difference is that the filling temperature can withstand high temperatures of 85-95°C. The liquid cylinder is round and made of sanitary grade 304 stainless steel. There is a page detector inside the liquid cylinder, which can monitor the liquid level in real-time. When the liquid level is too low, Automatic liquid level replenishment, the round liquid cylinder is more convenient to clean, and the mainstream micro-negative pressure filling method is used, which is suitable for various viscous drinks. Fully automatic mango juice beverage filling machine, suitable for beverage filling machines with various round bottles and square bottles. The plastic screw cap adopts a magnetic knob type. The aluminum cap has two types: a screw cap and a pressure cap. Different configurations are configured according to different outputs.

There are many products packaged in plastic, including large and small bottles of bottled water, various cans, and various types of glass bottles. According to the packaging type, it can be divided into multiple packaging quantities, including 2*3, 3*4, 4*4, 4*5. and other packaging methods. You can choose different equipment according to the required packaging method and automatic method. Equipment that uses plastic film packaging reduces transportation costs, and the cost of consumables is much cheaper than cartons. , cannot be affected by water droplets, etc., and is also suitable for use in humid areas, so it is very practical.

The PET bottles used in the fully automatic mango juice making line are blown by equipment that can blow the bottle. The bottle-blowing machine is made of a metal outer frame and has a series of functions such as automatic blank loading, heating, mold closing, and bottle blowing. The fully automatic bottle-blowing machine can switch between multiple bottles. It only needs to change the mold to switch between multiple bottles. Fully automatic bottle blowing output can be selected from a variety of outputs of 2000, 4000, 6000, and 9000 bottles/hour. Matching configurations: one out of two, one out of four, one out of six, full servo high-speed one out of six, and other machine types. The bottle-blowing machine is controlled by a one-button touch control, and its internal structure consists of inverters, PLC controllers, relay switches, air switches, and other components.

Mango juice processing steps 6: cooling

The temperature of filled mango drinks is relatively high after filling. In a long-term high-temperature state, it is easy to affect the taste of mango drinks and lose the nutrition of juice drinks. The temperature of the juice needs to be lowered to normal temperature. The temperature of the preform itself is also relatively high. Multi-stage cooling is used for cooling, which can avoid large temperature differences. Multi-stage cooling can reflow the water in the temperature zone with a close temperature for reuse. The water spray adopts spray-type water sprinkling, which can comprehensively Spray evenly. Mobile chain plates are suitable for a variety of applications.

The mango juice processing production line requires a series of equipment to complete the entire process from fresh fruit extraction to packaging. It contains many devices, each of which has its specific functions and effects. Only by combining and using them reasonably can high-quality products be produced.

-lp.jpg)