AGICO Industrial Mushroom Drying Oven

The AGICO Industrial Mushroom Drying Oven is a professional food dehydration equipment based on advanced hot air circulation technology. It is specifically designed for the edible mushroom processing industry, aiming to efficiently remove moisture from mushrooms through a precise and gentle drying process, significantly extending shelf life while maximizing the retention of their original shape, nutritional components, and rich flavor. This equipment is an ideal solution for mushroom processing plants, agricultural cooperatives, large farms, and food export enterprises to achieve large-scale and standardized production.

Send Enquire Now

Send Enquire Now

Features of Mushroom Dryer Machine

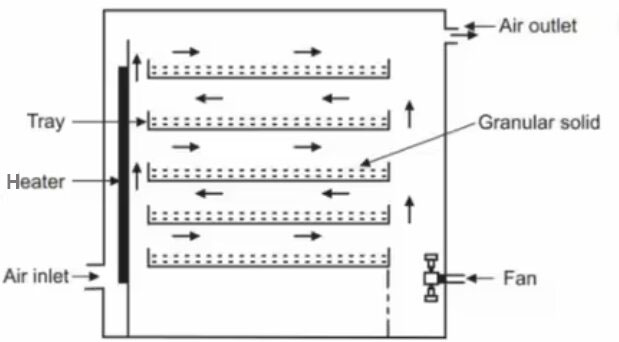

Efficient Hot Air Circulation System

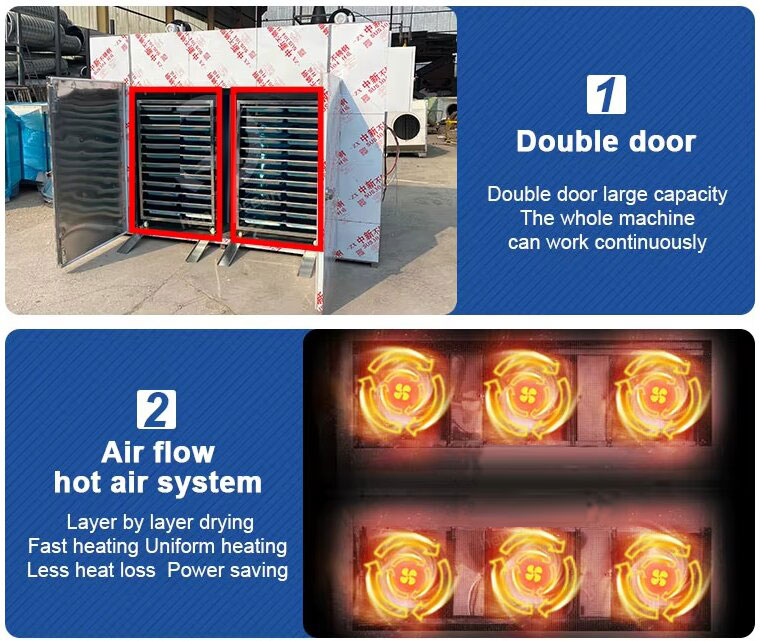

Utilizes high-temperature resistant, high-power fans and a scientifically designed air distribution system to create a powerful and uniform circulating hot air flow, ensuring no dead angles in the drying chamber. This guarantees fast and even dehydration for every part of the mushrooms, effectively preventing localized residual moisture or cracking.

Precise Temperature Control System

Equipped with an imported microcomputer PID intelligent temperature controller, with control accuracy up to ±1°C. Users can flexibly set the optimal drying temperature curve within a wide range from ambient temperature to 120°C, according to the process requirements of different mushroom varieties (e.g., shiitake, wood ear, oyster mushroom).

Energy-Saving and Eco-Friendly Design

The oven body features a double-layer stainless steel structure filled with high-density, environmentally friendly insulation material, ensuring high thermal efficiency and effectively preventing heat loss. It saves over 30% more energy compared to traditional drying equipment, meeting modern industrial energy conservation requirements.

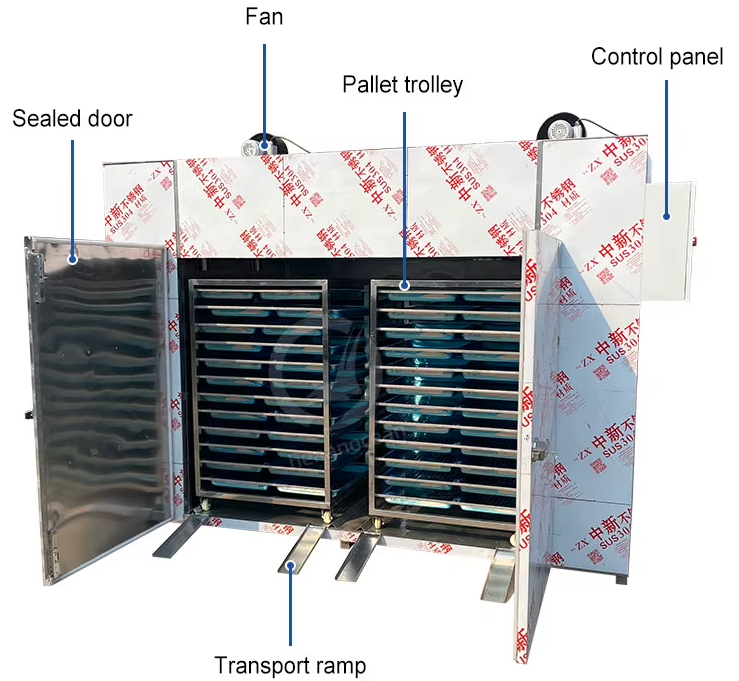

Struture of Mushroom Dryer Machine

Struture of Mushroom Dryer Machine

Contact us for product catalog

Hygienic and Durable Materials

All parts contacting the material (inner chamber, trays, trolleys) are made of food-grade 304 stainless steel, offering excellent corrosion resistance, contamination prevention, and ease of cleaning and maintenance, fully complying with international food safety standards like HACCP and GMP.

User-Friendly Design

Standard trolley-type structure allows for easy loading and unloading, enabling batch and continuous production. The control panel is simple and intuitive, making operation straightforward.

Comprehensive Safety Protection

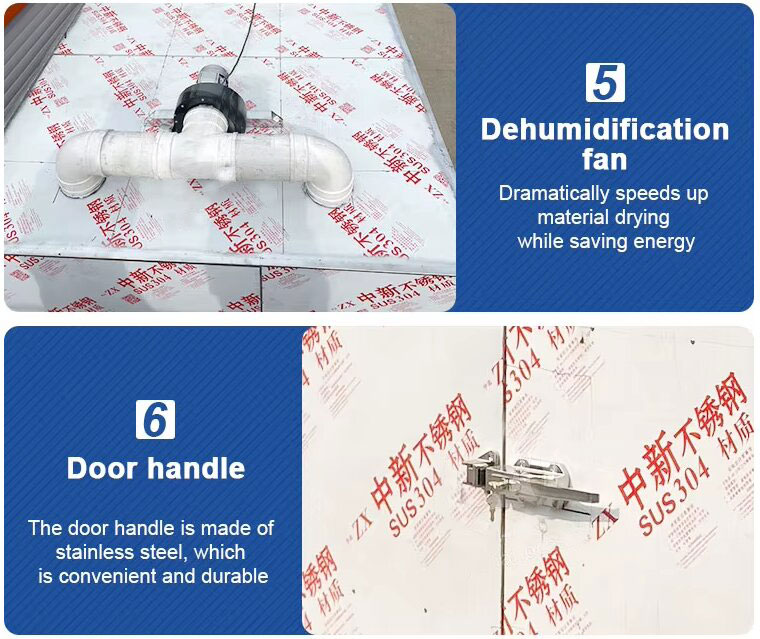

Integrated with multiple safety devices, including automatic over-temperature power-off, motor overload protection, and leakage protection, ensuring long-term stable operation and eliminating potential safety hazards.

Flexible Design

Multiple standard models are available, and customization is accepted. The drying oven size, number of tray layers, and number of trolleys can be customized based on customer production capacity needs. Various heat source options (electric, steam, or gas) are also available.

Technical Specifications

| Spec. of industry standard | specification | Batch drying capacity(kg) | Power(kW) | Steam to be consumed(kg/h) | Heat exchange area(㎡) | Velocity(m3) | Temperature different of the top and the bottom(℃) | Baking trays | Overall dimensions (LxWxH)mm | Baking cart to be used (set) |

|---|---|---|---|---|---|---|---|---|---|---|

| RXH-5-C | CT-C-O | 25 | 5 | 5 | 5 | 3400 | ±2 | 8 | 1400x1200x1600 | 0 |

| RXH-14-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400x1200x2000 | 1 |

| RXH-14-C | CT-C-Ⅰ | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300x1200x2000 | 2 |

| RXH-27-C | CT-C-Ⅱ | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300x2200x2000 | 4 |

| RXH-41-C | CT-C-Ⅲ | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300x3220x2000 | 6 |

| RXH-54-C | CT-C-Ⅳ | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4450x2200x2000 | 8 |

| RHX-25-A | High effect and high temperature far infrared sterilization oven. The power will be equipped in accordance with the requirements of temperature. | 1200x1000x1600 |

|

|||||||

Application

Primary Application: Drying various edible mushrooms, such as shiitake, king oyster mushroom, oyster mushroom, enoki mushroom, wood ear, tremella, lion's mane mushroom, etc.

Extended Applications:

- Vegetables: Chili peppers, carrots, scallions, garlic, potatoes, etc.

- Fruits: Apples, bananas, mangoes, kiwifruit, grapes, etc.

- Chinese Herbal Medicines: Goji berries, chrysanthemums, astragalus, ginseng slices, etc.

- Others: Nuts, meats, and aquatic products drying.

Advantages of Mushroom Drying Machine

- High-Quality Drying: Uniform hot air circulation ensures the finished dried mushrooms have a natural color, plump appearance, and uniform quality, effectively locking in nutrients and natural flavor, significantly enhancing product market competitiveness.

- High Efficiency & Energy Saving: Drying efficiency is several times higher compared to traditional sun-drying or ordinary ovens, while significantly reducing energy consumption, helping customers effectively control production costs and improve ROI.

- Easy Operation: The trolley design greatly simplifies the loading/unloading process. The intelligent control system allows for "set-and-forget" operation, reducing dependence on operator skill and saving labor costs.

- Safe and Reliable: Multiple safety protection mechanisms and robust industrial-grade manufacturing standards ensure stability and reliability during continuous high-load operation, extending the equipment's service life.

- Long Lifespan & Low Maintenance: The all-stainless-steel construction and high-quality core components ensure durability. Daily maintenance requires only simple cleaning, resulting in very low maintenance costs.

Operation & Maintenance Guide

Basic Operating Procedure:

- Preheating: Set the desired temperature and start the equipment for preheating.

- Loading: Spread fresh or pre-processed mushrooms evenly on the stainless steel trays and push the trolleys into the drying oven.

- Setting: Set the drying temperature and time on the control panel.

- Start-up: Close the door and start the equipment to begin the drying process.

- Cooling & Unloading: After drying is complete, unload the mushrooms from the trolleys after natural or forced cooling.

Cleaning & Maintenance:

- Daily Cleaning: Clean residues from trays and the inner wall promptly after each use.

- Regular Inspection: It is recommended to monthly check the fan operation and for dust accumulation on heating elements.

- Long-Term Storage: Clean the equipment inside and out, and keep the interior dry and ventilated.

-lp.jpg)