AGICO Multilayer Belt Food Dryer: Revolutionizing Industrial Drying with Unmatched Efficiency & Quality

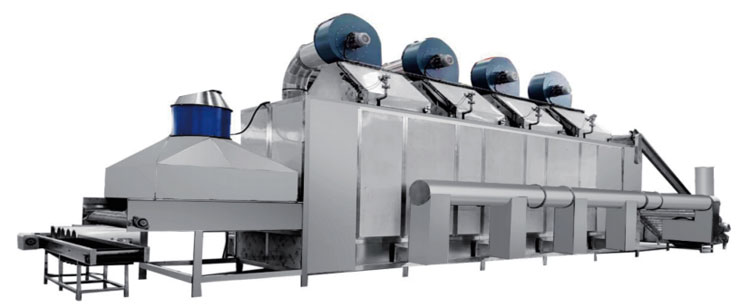

In the modern food processing industry where health, efficiency, and sustainability are paramount, AGICO introduces its cutting-edge Multilayer Belt Food Dryer. Engineered with precision and innovation, this industrial-grade solution redefines drying technology—delivering superior product quality, remarkable energy savings, and robust operational reliability for global manufacturers.

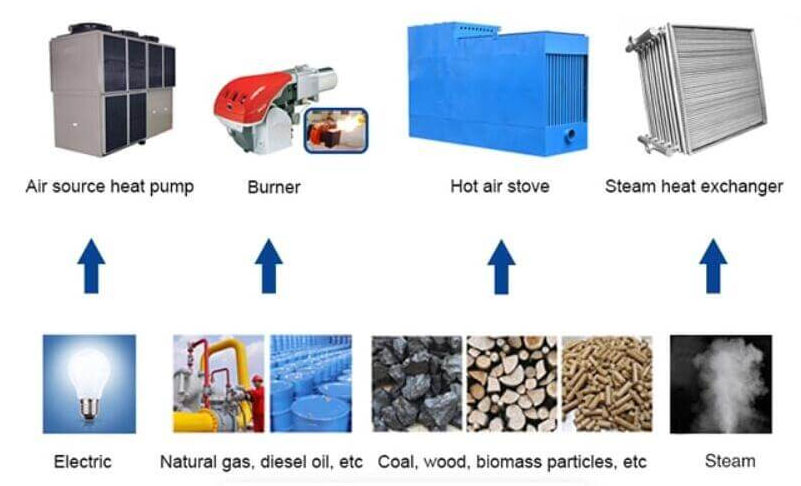

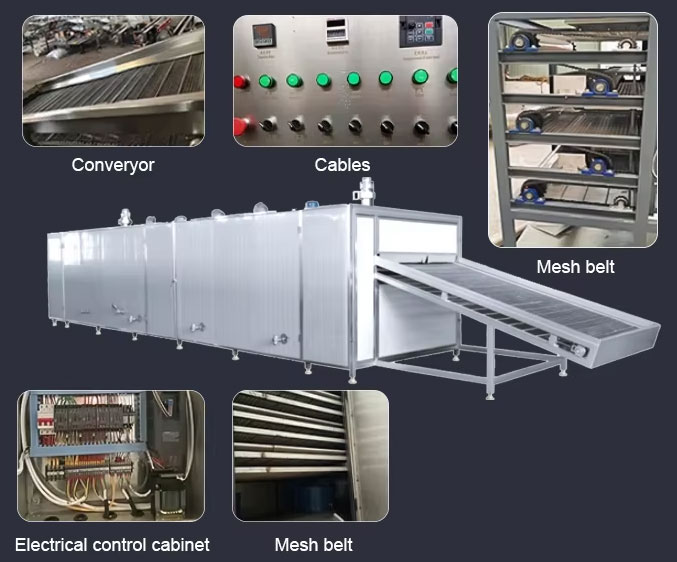

AGICO's mesh belt drying equipment features customizable designs that utilize hot air as the drying medium to facilitate moisture diffusion, vaporization and evaporation through continuous material contact. The system offers multiple heating options including electric, steam and hot air heating, with fully customizable production capacity and tailored drying temperature profiles/cycle systems adapted to specific product requirements. Comprising a belt conveyor, automatic feeding system and drying chamber, this intelligent equipment delivers automated feeding/discharging functions and precise process control. Key advantages include significantly reduced heat consumption, high production efficiency, user-friendly operation, easy maintenance and broad application versatility for diverse material drying applications.

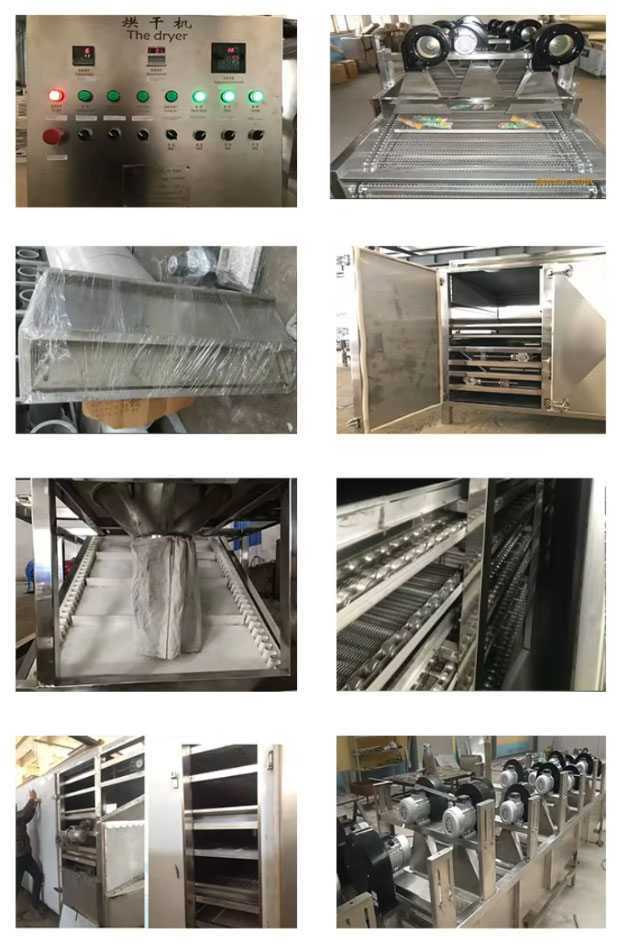

AGICO Food Dryer Configuration & Operation

| Component | Function |

|---|---|

| Auto Feeding System | Precision-spreading mechanism ensures uniform material distribution |

| Multi-Tier Belts | 3-15 layer SUS304 mesh conveyor (customizable) for progressive drying |

| Heat Exchange Chamber | Vertical airflow design with ±1°C temperature control |

| Intelligent Controls | PLC-managed drying cycles with moisture sensors |

Drying Process Workflow:

- Loading: Wet materials enter via automated feeder with homogenizing spreader

- Vertical Conveyance: Product travels downward through multi-level drying zones

- Counterflow Heating: Hot air rises from bottom chamber (pressure differential design)

- Tumbling Action: Material self-turns on mesh belts, enabling 360° heat exposure

- Moisture Extraction: Evaporated water vapor exits through top exhaust

- Discharge: Finished product with ≤5% residual moisture at output conveyor

Why Choose AGICO Mesh Belt Food Dryer?

Traditional drying methods struggle with uneven heating, high energy costs, inconsistent output, and limited capacity. The AGICO Multilayer Belt Dryer eliminates these pain points through revolutionary design:

- AGICO’s Multi-Tier Belt System Maximizes Output:

- Precision Temperature Control Saves Energy:

- Uniform Airflow Penetration Ensures Premium Quality:

- Rapid 95%+ Moisture Removal Extends Shelf Life:

- Food-Grade Construction Guarantees Safety:

- Industrial-Grade Reliability for 24/7 Production:

- Intuitive Control & Low Maintenance Design:

Applications of AGICO Mesh Belt Food Drying Machine

Ideal for drying:

- Vegetables: Spinach, carrots, onions, peppers, cabbage

- Fruits: Apples, bananas, kiwis, berries, goji berries

- Mushrooms: Shiitake, oyster, wood ear, enoki

- Seafood: Fish fillets, shrimp, scallops

- Botanicals: Herbs, tea leaves, medicinal plants

- Grains & Legumes: Corn, soybeans, peas

Technical Specifications of Mesh Belt Food Drying Machine

| Parameter | Specification |

|---|---|

| Model | AGICO-MBD Series |

| Drying Capacity | 200–300 kg/hour (varies by material) |

| Temperature Range | 50°C – 120°C (adjustable) |

| Belt Material | Stainless Steel Mesh (SUS304/316) |

| Belt Width | 1.2m, 1.6m, 2.0m (customizable) |

| Number of Layers | 3–15 tiers (configurable) |

| Heat Source Options | Electric / Steam / Gas / Biomass |

| Control System | PLC + Touchscreen HMI |

| Moisture Reduction Rate | Up to 95%+ |

| Power Requirements | 18–75 kW (model-dependent) |

| Footprint (L×W×H) | Custom-designed per capacity needs |

Advantage

- Turnkey Solutions – Custom engineering for your raw material and output goals

- Global Compliance – CE, ISO, and industry-specific certifications

- Lifetime Support – Installation, training, spare parts, and technical service

Contact our engineering team today to configure your optimal Multilayer Belt Dryer system. Discover how AGICO technology can boost your productivity, slash operating costs, and capture new markets with premium-quality dried products.

-lp.jpg)