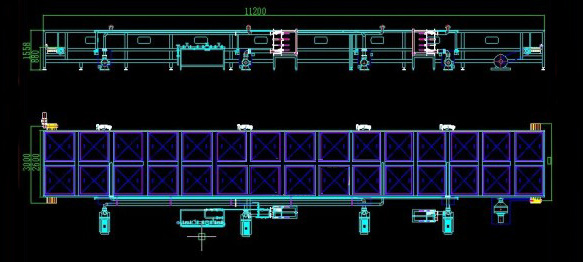

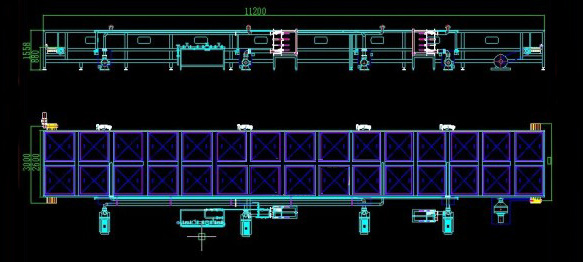

Continuous Spraying Sterilizer Introduction

Continuous spraying sterilizer is widely applicable for sterilizing and cooling various bottled or canned fruit juice, liquor, other beverage and seasoning etc. Continuous spraying sterilizer is a method of handling containers that have already been filled. The untreated product is poured into containers, closed, and conveyed via conveyor belts into the continuous spraying sterilizer. In the various temperature zones in the continuous spraying sterilizer, the container is sprayed with water at different temperatures, that is, the sterilization phase and the cooling phase.

Continuous Spraying Sterilizer Working Principle

When conveyor belt transport bottles or cans into tunnel, they will experience 4 periods, namely preheating stage, heating stage (sterilization stage), precool stage, and cooling stage. After these four stages spraying, the product was sterilized and the temperature is lowered down to the room temperature. All the used water shall flow back to the bottom tank for recycling.

Classification of Continuous Spray Sterilizers

Automatic spray sterilizer: using advanced PLC automatic computer program control, the whole process operation production control can be carried out according to the set process requirements.

Semi-automatic spray sterilizer: The whole process of operation is controlled semi-automatically. The operator can control the pumps, valves, and return flow function from the control panel, and the sterilization temperature is maintained by PID (temperature control), and the change in sterilization temperature is accurately recorded on the recorder.

Continuous Spraying Sterilizer Features

-

The sterilizer temperature can control automatically and the sterilization time can be adjusted.

-

The machine is equipped with 4 temperature zone, temperature gradient is small, which can guarantee good sterilizing effect, and can reduce the bottle breaking rate.

-

The continuous spraying sterilizer can be designed according to the sterilization condition and output suggested by customers.

-

Steam consumption is adjusted according to temperature.

-

The material of frame and machine body is made of 304-stainless-steel.

-

Production capacity: 100-400 can/min Sterilizing temperature: 100℃. Steam pressure: 0.4 Mpa.

-

Multi-process combination, reasonable process, can handle a variety of materials.

-

The sterilization temperature is controlled by a PLC touch screen.

-

The total processing time can be controlled by frequency conversion, which can be adjusted according to the production process.

Performance Characteristics of the Continuous Spraying Sterilizer :

-

Suitable for various sizes of packaging products.

-

There is a transition section between sterilization and cooling to ensure the taste of the product.

-

All bearings adopt an anti-corrosion system to ensure the service life of the equipment.

-

The production process is continuous. The machine adopts stepless speed regulation, and the sterilization time is adjustable.

Packing and Delivery

-lp.jpg)