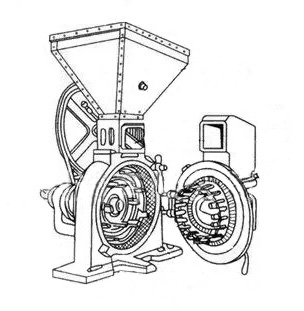

Fruit Crusher Machine Application

The fruit crusher machine is used for crushing various kinds of fruits and vegetables, including tomato, apple, pear, onion, chili, strawberry, blackberry and carrot, etc, and crushing raw materials into small diameter particles, convenient the operation of the next step. It is characterized by the automatic separation of fruit juice and pomace, which can be combined on the production line or produced by a single machine.

All places that come into contact with fruits are made of stainless steel and high-quality edible rubber, which has good corrosion resistance, will not contaminate materials, and ensures food hygiene.

As long as the fruit crusher machine changes the screen of different specifications and adjusts the lead angle of the scraper, it can change the different pulping speeds and obtain satisfactory results. This machine has the characteristics of easy operation, easy cleaning, safety and hygiene, continuous feeding, a wide range of applications, etc., and is an ideal machine for juice processing.

|

|

Fruit Crusher Machine Features

- The fruit and vegetable crushing machine structure is hammer slice type so the crusher can not damage the seed and guarantee the color and flavor.

- Closed form hopper type designing to avoid the splashing of the material which can make the material crush adequately.

- The fruit and vegetable crusher receiving tank is made of stainless steel. It also be installed full- auto liquid level controller to protect and balance the pretreatment equipment.

- The fruit and vegetable crusher runs stability and easy to operate. The material is stainless steel and with perfect surface, firm and durable.

AGICO prompts you to pay attention to the following points:

- The machine shall not be subject to shock or severe vibration during shipment.

- When the fruit crusher machine is installed, it is recommended to fix it with foot bolts, and when the ground quality is better, it can be fixed with expansion screws.

- After installation, remove the internal dirt of the machine, and check that the spindle rotates flexibly and has no jamming phenomenon.

- The housing should be filled with the appropriate amount of oil to lubricate the bearing. (Note: The oil in the housing must be changed frequently! Operation steps: first open the oil drain hole at the bottom of the housing, drain the dirty oil, and then inject oil from the upper part of the housing.)

- After the power supply is turned on, the motor steering must be checked to ensure that the motor steering is consistent with the steering mark of the machine, and the production can be started after it is correct.

| Model | production capacity(T/H) | Power(kw) | Size(mm) |

|---|---|---|---|

| CPJ-20 | 20 | 30 | 1830×1100×2500 |

| CPJ-10 | 10 | 15 | 1280×1100×2035 |

| CPJ-5 | 5 | 7.5 | 1130×850×1850 |

| CPJ-2 | 2 | 3 | 1000×600×1500 |

About use and maintenance

The feeding should be carried out after the machine is operating normally, and the feeding must be uniform.If abnormal noise and vibration are found during work, it should be stopped for inspection and eliminated faults before use.

If you do not plan to use it in the future, you should clean it, remove internal stagnant water, and store it in a dry and ventilated room.

-lp.jpg)