What is a IQF Tunnel Quick Freezer?

A Tunnel Quick Freezer is an industrial-grade refrigeration equipment designed for the continuous, large-scale, rapid freezing of food, pharmaceuticals, and other materials. Its name derives from its physical structure – a long, tunnel-like insulated enclosure equipped with a continuously moving conveyor belt. Products enter from one end of the tunnel and are rapidly frozen by intensely controlled, low-temperature, high-velocity airflow as they move along the conveyor to the opposite end.

Its core working principle is achieving IQF (Individual Quick Freezing). Unlike traditional batch freezing methods (like freezer cabinet freezing), the Tunnel Quick Freezer, through precise mechanical and aerodynamic design, ensures that each individual product item (such as a single strawberry or a single shrimp) is frozen quickly and independently, without sticking to others. This rapid freezing process causes the water inside the product to form extremely tiny ice crystals, thereby maximizing the protection of the cellular structure. When the product is thawed, it retains its original color, flavor, texture, and nutritional content to the greatest possible extent, with a taste close to fresh.

Therefore, the Tunnel Quick Freezer is a key piece of equipment in the modern food processing industry for ensuring product quality, improving production efficiency, and enabling large-scale production.

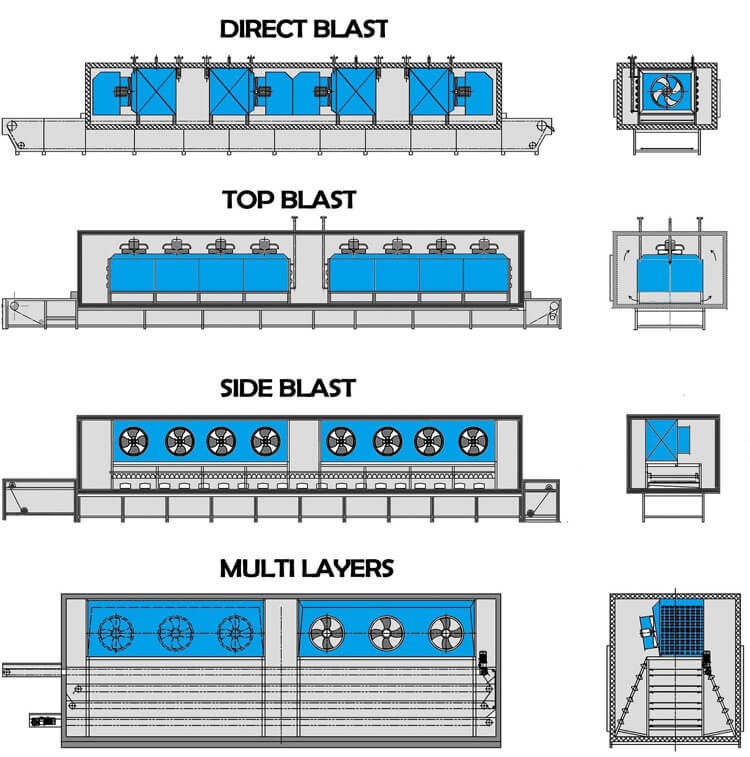

Types of Tunnel Quick Freezer

Types of Tunnel Quick Freezer

Components of a Tunnel Quick Freezer

Contact us for product catalog

Contact us for product catalog

A modern tunnel quick freezer is an integrated system comprised of several key components working in unison:

Insulated Enclosure:

A well-insulated tunnel structure, typically with stainless steel panels and high-density polyurethane foam, designed to contain the cold environment and minimize energy loss.

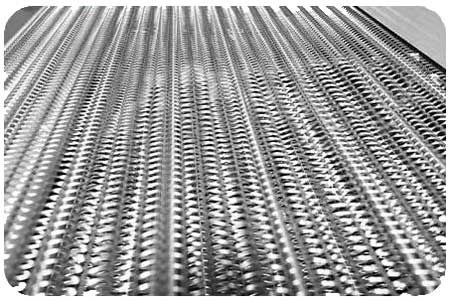

Three-Stage Conveyor System:

Often configured as a multi-tier or multi-stage mesh belt system. This compact design maximizes freezing capacity within a small footprint. The speed is adjustable, allowing for precise control over freezing time for different products.

High-Efficiency Refrigeration System:

At the heart of the freezer, this system utilizes environmentally friendly refrigerants and energy-efficient compressors. It is designed for powerful cooling, low operating costs, and stable, durable performance.

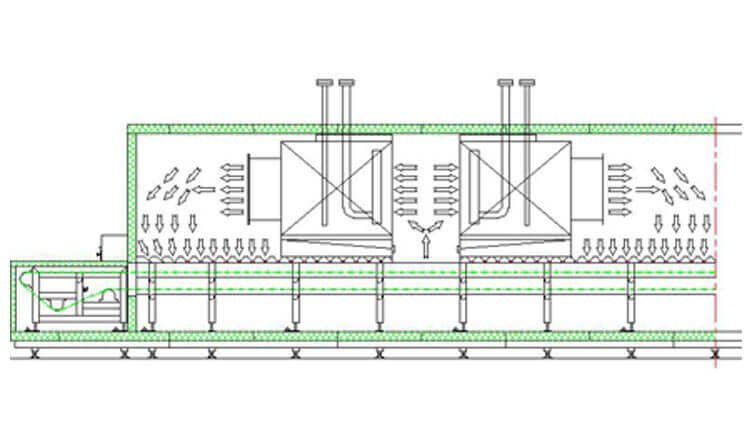

Patented Airflow Circulation System:

This system features a unique air guide device that ensures a rational and uniform distribution of high-velocity cold air. This "wind curtain" fully exposes all materials to the intense cold, guaranteeing high freezing efficiency and exceptional IQF results.

Intelligent Control System:

Centered on a PLC and user-friendly interface, the system offers flexible operation with both automatic and manual refrigeration modes. This allows for easy adjustment based on production needs, ensuring consistent results and simple operation.

Tunnel Quick Freezer

Tunnel Quick Freezer Tunnel Freezer Warehouse Body

Tunnel Freezer Warehouse Body Mesh Belt of Tunnel Quick Freezer

Mesh Belt of Tunnel Quick Freezer Tunnel Freezer Cooling Fan

Tunnel Freezer Cooling FanFeatures of IQF Tunnel Quick Freezing Machine

The integration of these components delivers a host of compelling features:

- Superior IQF Quality & Product Integrity: Rapid freezing forms tiny ice crystals, preserving the cellular structure of the food. This maximizes the retention of texture, color, flavor, and nutritional value after thawing.

- High Efficiency & Significant Energy Savings: The compact structure and optimized air duct design contribute to excellent freezing performance while consuming 30-40% less electricity compared to conventional models. This translates to dramatically lower operating costs.

- Continuous, Automated Operation: The fully automatic "load-freeze-unload" process saves significant time and labor, seamlessly integrating into industrial production lines for non-stop operation.

- Hygienic & Safe: The use of food-grade materials, smooth surfaces, and a refrigeration system that effectively suppresses bacteria and odors ensures compliance with the highest food safety standards (HACCP, GMP).

- Flexibility and Durability: The adjustable speed conveyor and flexible control modes allow for the processing of various products. Built with robust components and featuring a conveyor tension adjustment device for smooth operation, the machine is designed for a long service life and reliable performance.

Get a free quote

Get a free quote

Technical Parameters

| Models | SSD1-300 | SSD1-500 | SSD1-1000 | SSD1-1500 | SSD2-1000 | SSD2-2000 | SSD2-3000 |

|---|---|---|---|---|---|---|---|

| Capacity(kg/h) | 300 | 500 | 1000 | 1500 | 1000 | 2000 | 3000 |

| Refrigeration capacity(kw) | 50 | 80 | 160 | 240 | 160 | 300 | 400 |

| Size |

9040x2770 x2700 |

11000x3400 x2700 |

19000x3400 x2700 |

19000x4800 x2700 |

11000x6680 x2700 |

19000x6680 x2700 |

19910x4140 x3800 |

| L×W×H(mm) | |||||||

| Installed Power(kw) | 5.3 | 9.5 | 19 | 30 | 19 | 38 | 53 |

| Feed temperature(℃) | +15℃ | ||||||

| Discharge temperature(℃) | -18℃ | ||||||

| Circulating temeprature(℃) | -35±2℃ | ||||||

| Freezing time(min) | 20~60 | ||||||

| Refrigerants | Customized | ||||||

Application

This versatile freezer is indispensable across the food industry for products such as:

- Fruits & Vegetables: Berries, corn, peas, diced blends, french fries.

- Seafood: Shrimp, scallops, fish fillets, crab meat.

- Meat & Poultry: Chicken chunks, beef strips, meatballs, sausages.

- Prepared Foods: Dumplings, spring rolls, pizza toppings, ready meals.

Get a free quote

Get a free quote

Advantages of AGICO Tunnel Quick Freezers

Among numerous competitors, AGICO Tunnel Quick Freezers stand out, forming unique competitive advantages through our relentless pursuit of technology, quality, and service:

Deeply Customized Engineering Solutions:

We understand that a "one-size-fits-all" approach is not optimal. AGICO is not just an equipment supplier but your solution partner. Starting from your specific product characteristics, output targets, factory layout, and budget, we provide comprehensive customization from tunnel length, belt width, freezing temperature to specific airflow patterns, ensuring the equipment perfectly fits your production line and maximizes your return on investment.

Patented High-Efficiency Airflow Organization Technology:

The core of freezing uniformity and efficiency lies in airflow. AGICO invests heavily in R&D and possesses patented air guide and multi-stage fan configuration technologies that create an exceptionally uniform and stable vertical or horizontal airflow field, free of dead spots or short-circuiting. This means every product across the tray achieves consistent freezing results, eliminating issues of partial under-freezing or over-freezing, fundamentally guaranteeing uniform product quality.

Total Lifecycle Cost Optimization:

We focus not only on the initial equipment purchase cost but also on its operational costs over a decade or more. AGICO equipment utilizes top-tier energy efficiency compressors and variable frequency driven EC fans that automatically adjust power based on load, saving 15%-25% energy compared to conventional equipment. Simultaneously, we use the highest quality components and materials, significantly reducing failure rates and maintenance frequency, ensuring ultra-long service life and high online availability, creating continuous value for you.

Smart Connectivity and Forward-Looking Design:

AGICO's intelligent control system is not only user-friendly but also features data logging, remote monitoring, and predictive fault diagnosis. You can view equipment status in real-time via the network, and our engineers can provide remote technical support. The device interfaces are open, facilitating future integration with factory MES systems, laying the groundwork for building a "smart factory."

End-to-End Service Commitment:

Our partnership begins with consultation but does not end with delivery. AGICO provides one-stop service from project planning, installation guidance, commissioning & training, to lifelong after-sales support. We have a globally distributed rapid-response service network and sufficient spare parts inventory, ensuring our professional support reaches you promptly when needed, completely eliminating your concerns.

-lp.jpg)