AGICO Fruit Hot Air Circulation Dryer Machine

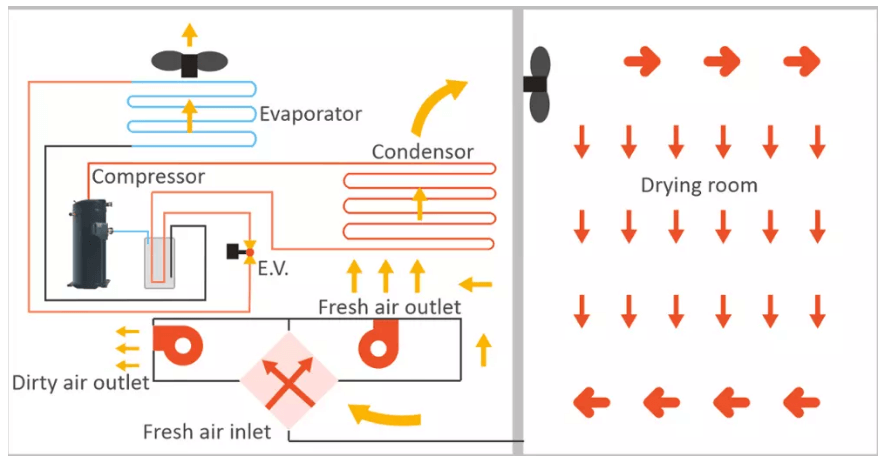

The CT-C series hot air circulation fruit and vegetable drying oven is equipped with a low-noise, high-temperature-resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, increasing the oven's thermal efficiency from the traditional drying room's 3%-7% to the current 45%-50%, with a maximum thermal efficiency of up to 60%. The successful design of the CT-C series hot air circulation oven has elevated China's hot air circulation ovens to advanced domestic and international levels, saving significant energy for the country and improving the economic efficiency of enterprises. In 1990, the industry standard was issued by the State Pharmaceutical Administration, unifying the model as RXH.

Most of the hot air circulates within the chamber, ensuring high thermal efficiency and energy savings. With forced ventilation and adjustable air distribution plates inside the chamber, materials are dried evenly. The heat source can be steam, hot water, thermal oil, electricity, or a hot air furnace, offering a wide range of options. The fruit drying machine operates with low noise and smooth performance. It features automatic temperature control and easy installation and maintenance. With a broad range of applications, it can dry various materials, making it a versatile drying equipment.

Fruit Drying Oven Model and Specification

| Spec. of industry standard | specification | Batch drying capacity(kg) | Power(kW) | Steam to be consumed(kg/h) | Heat exchange area(㎡) | Velocity(m3) | Temperature different of the top and the bottom(℃) | Baking trays | Overall dimensions (LxWxH)mm | Baking cart to be used (set) |

|---|---|---|---|---|---|---|---|---|---|---|

| RXH-5-C | CT-C-O | 25 | 5 | 5 | 5 | 3400 | ±2 | 8 | 1400x1200x1600 | 0 |

| RXH-14-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400x1200x2000 | 1 |

| RXH-14-C | CT-C-Ⅰ | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300x1200x2000 | 2 |

| RXH-27-C | CT-C-Ⅱ | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300x2200x2000 | 4 |

| RXH-41-C | CT-C-Ⅲ | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300x3220x2000 | 6 |

| RXH-54-C | CT-C-Ⅳ | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4450x2200x2000 | 8 |

| RHX-25-A | High effect and high temperature far infrared sterilization oven. The power will be equipped in accordance with the requirements of temperature. | 1200x1000x1600 | ||||||||

Applications of hot air circulation drying oven

The dryer oven is suitable for heating, curing, drying, and dehydrating materials and products across various industries, including pharmaceuticals, chemicals, food, agricultural and aquatic products, light industry, and heavy industry.

Typical applications include:

- Food Processing: Dehydrated vegetables, dried fruits, sausages, and other food products.

- Pharmaceuticals: Raw medicinal materials, herbal slices, extracts, powders, granules, pills, and packaging bottles.

- Chemicals: Pigments, dyes, plastic resins, and coatings.

- Industrial Products: Electrical components, paint baking, and other industrial drying needs.

Features of fruit and vegetable drying oven

Multiple Heating Options:

- Water, steam, electricity, thermal oil, dual electric-steam, and hot air furnace (six modes available).

Operating Temperature Ranges:

- Water/Steam Heating: 50–140°C (max 150°C).

- Hot Air Furnace/Thermal Oil: 50–300°C.

- Electric Heating: 50–650°C.

Excellent Sealing Performance:

- Fully sealed construction with a unique guide rail sealing mechanism to ensure airtight operation.

Dual-Door Mechanical Interlock (for double-door models):

- Prevents simultaneous opening for safety and heat retention.

Quick-Disassembly Design:

- All internal components can be rapidly removed and reinstalled for easy cleaning.

Customizable Control System:

- Optional text display or touchscreen interface.

GMP Compliance for Pharmaceutical Use:

- Suitable for sterilization and drying of medicines and equipment under pharmaceutical "GMP" standards.

Expert Design & Manufacturing:

- Combines international expertise with domestic "GMP" requirements for reliable performance.

Successful case

Fruit drying oven of CT-C series are used to dehydrate all kinds of fruits and vegetables, like, lemon, apple, banana, orange, blackberry, mango, blueberry, strawberry, peach, kiwifruit, carrots, cucumbers, ginger, onions, garlic and so on.

Service Commitment

1. Design & Manufacturing

During the design and production phases of equipment processing, we actively incorporate customer feedback, with special consideration given to the buyer’s site conditions and utility requirements. This ensures the equipment achieves optimal performance and integration.

2. Installation & Commissioning

Upon equipment delivery, we dispatch dedicated technicians to guide on-site installation and oversee commissioning until full operational status is achieved. The buyer is responsible for accommodation and round-trip airfare.

3. Training

Prior to normal operation, our commissioning team will conduct comprehensive training for the buyer’s personnel, covering: equipment maintenance & care, troubleshooting common issues, and standard operating procedure

4. Quality Warranty

All equipment carries a 1-year warranty. During this period: 1. Non-human-related failures: Free repair/replacement. 2. Human-induced damages: Prompt repair at cost price.

5. Lifetime Support

We supply high-quality spare parts at competitive prices throughout the equipment’s lifecycle, backed by lifelong technical support services.

-lp.jpg)