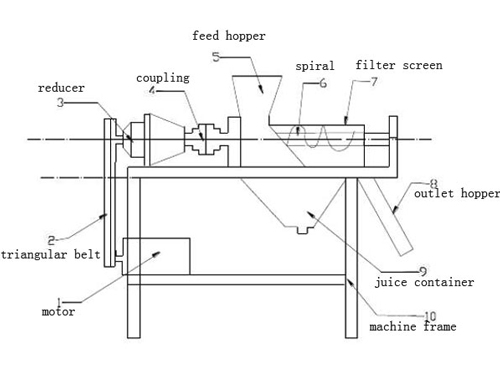

Details of spiral juice extractor

Spiral juice extractor can be used to squeeze juice from fruits and vegetables, and separate solid and liquid from mixed materials. It applies to wide range of materials, from rough solid to slippery solid and fluid materials, with little chance of slipping or blocking. Compared with traditional fruit juice extractor, it has a higher juice extraction rate of 85%. In this way, spiral juice extractor can make higher profit for you.

The spiral juice extractor is a combination of advanced technology and superior materials. It squeezes fruit juice with a propelling screw axis, and integrates the function of crushing, extracting and discharging. The main component is a spiral blade, whose bottom diameter increases along the outlet side, and the thread peach keeps shrinking.

When raw materials are propelled into the chamber, they are squeezed by the shrinking helical cavity. The extracted juice flows into the collector through the sleeve at the bottom, while the slag is discharged through the ring gap between the spiral and taper part of the pressure regulator. You can rotate the regulator along the shaft to adjust the clearance, so as to change the resistance of discharge and slag yield. If the clearance is too small, some slag will come out with fruit juice, which increases the juice yield but sacrifice the quality. The clearance is supposed to be determined by the process technique.

How to operate spiral juice extractor correctly

As the rotating speed is rather high in spiral juice extractor, it’s not advisable to work continuously for long time, or the temperature will goes up and impair the electric motor.

The high-speed rotation of spiral juice extractor have certain risks, therefore the safety protection is indispensible. Fruit juicers are usually equipped with automatic locking device that prevent running if the accessories are not in place. When choosing spiral juice extractors, check if it is equipped with safety device, and turn on it carefully if the accessories are in absence.

After frequent use, there are usually some slag remained in the machine. To ensure the sanitation of fruit juice, washing the machine regularly is necessary. Without a screen mesh, spiral juice extractor is able to discharge fruit slag while extracting juice, which facilitates cleaning. But the spare parts in spiral juice extractor is a little more, which takes you much effort to take apart and wash.

How to judge the quality of spiral juice extractor

The Extracting Effect of spiral juice extractor

Superior juice extractor can achieve high juice extraction rate, the slag from whom contains little water content. You can ask the sales to present the extracting effect with various kinds of fruits on the spot. Such tests can manifest the real capacity of the spiral juice extractor.

The quality of components

Pay attention to the components of spiral juice extractor, especially the blades and shafts. Make sure they are solid and durable, or they can dramatically increase your maintenance cost. Make it clear how long is the guarantee period, and where the manufacturer supply spare parts.

Rotating speed

The best rotating speed of spiral juice extractor is 70-90 rpm, and high quality spiral juice extractor is supposed to be under 100 rpm. Besides, the rotating speed should be uniform, with little noise or vibration. Check if it can stop quickly when you shut it down.

The exterior of spiral juice extractor

The shell of juice extractor influence the juice quality. Make sure it is clean and stable in chemical property, without strange smell or impurities.

-lp.jpg)