Background

With the development of science and technology and the improvement of people’s living conditions, it is understandable for people to pursue of high-quality life. Apart from eating fruits, more and more people begin to drink fruit juice which has higher nutritional value. So fruit juice processing industry comes into a new historic developing period. On this occasion, spiral juice extractor for fruit is becoming very popular for making nutritional fruit juice. And spiral juice extractor is convenient to operate and easy to clean.What is spiral juice extractor?

In daily life, spiral juice extractor is not only the common food mechanical equipment, but also supplies the requirements of juicing for some enterprises and catering industry in an effective and sanitary way. It not only can be combined with production line but also can as a single machine production to process fresh juice. Spiral juice extractor is used to extract fantastic and fresh juice not only from fruits such as apple, pear, peach, orange, pineapple and grape etc. but also from vegetables like carrot, tomato, ginger and celery etc. In addition, spiral juice extractor can extract berries after they are crushed and pre-boiled.

|

|

|

|

Components and working principle of spiral juice extractor

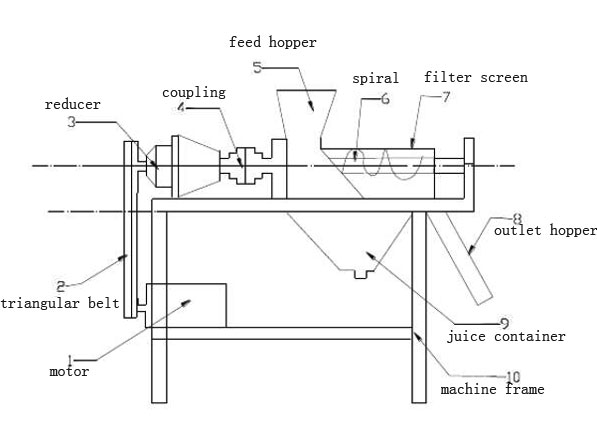

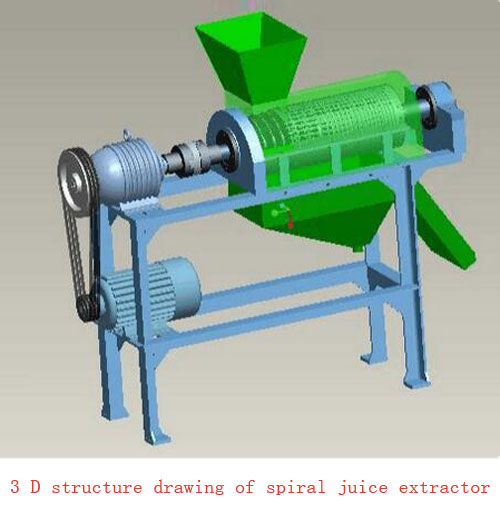

Just like other machineries, spiral juice extractor is composed of several important parts. And the simple structure of spiral juice extractor is shown in the following figure:

Just as shown in the figure, the main components of spiral juice extractor consist of motor, triangular belt, feed hopper, spiral, filter screen, juice container, reducer and coupling etc. And the working principle is as follows: the motor drives the reducer transmission through the triangular belt, when raw material is added into the feed hopper, they are propelled by the spiral, then the pressure makes the raw material to be extracted into juice, next, the finished juice will flow into the juice container through the filter screen, simultaneously, the residues are pushed out of the circular gap. The circular gap can be adjusted by the movement towards the axial direction In order to adjust the juice extracting rate.

Announcements of spiral juice extractor

- Generally speaking, we know there are many manufacturers and suppliers of spiral juice extractor, so the specification is different from each other. But most of the materials which can be touched with fruit raw materials of spiral juice extractor adopt the high quality stainless steel. And most of the packing form is wooden case.

- When using the spiral juice extractor, there is a critical aspect should be pay attention to. It is that the size of the circular gap should be the proper in accordance with the special requirements.

- When put the raw material into the feeding hopper, they must be put evenly, and at the same time, the raw material must be pretreated, for example, raw material has been washed and enucleated. And make sure there are not any dopants.

- Each time after the spiral juice extractor works, it should be cleaned overall. And the filter should be cleaned with water and brush after every shift of work.

-lp.jpg)