Fruit and vegetable juice drinks use fresh fruits or vegetables as raw materials, the juices are obtained by pressing or other methods, and then drinks made by mixing and sterilizing. Fruit and vegetable juice drink can be divided into two types: clear juice and muddy juice. Fruit and vegetable juice requires clear, transparent or uniform turbidity, but it is difficult to meet the requirements during the period of storage and sales, turbidity and precipitation often occur.

Causes of turbidity and precipitation in fruit and vegetable juice drinks

Causes of turbidity and precipitation in clear juice

- The fruit and vegetable juice beverage is not completely sterilized in the process of processing, or is polluted by microorganism after sterilization. Microorganisms grow and propagate, decompose pectin in the fruit and vegetable juice, and produce precipitating materials. Microorganisms also produce precipitation after they die.

- Inadequate filtration in the production also produce precipitation.

- The processing water can not meet the requirements of soft drink water, and the content of anion and cation in water is higher than that of soft drink. It reacts with some constituents in fruit and vegetable juice and produces precipitation.

- The quality of sugar or food additives used in mixing is poor or excessive, which can cause turbidity or precipitation.

Causes of turbidity and precipitation in muddy juice

- There is residual pectinase in the fruit and vegetable juice, and the pectin in the fruit and vegetable juice is gradually hydrolyzed under the influence of pectinase to reduce the viscosity of the fruit and vegetable juice, thus causing the precipitation of the suspended substance.

- The anions and cations in the processed water reflect with the organic acids in the fruits and vegetables juice, and destroy the pH value and the electrical balance of the fruit and vegetable juice system, thus causing the precipitation of the colloidal substance and the suspended substance.

- Microbial propagation breaks down pectin in vegetable and fruit juices and produces precipitation.

- The sugar used in the preparation contains protein, which can produce precipitate reflect with tannin materials in the fruit and vegetable juice.

- In the fruit and vegetable juice beverage, the pulp is too big or uneven in size, or the viscosity of the fruit and vegetable juice beverage system is low, the flesh particles lack enough buoyancy to counteract their gravity and precipitate under the action of gravity.

Control measures in the production of fruit and vegetable juice drink

In the event of turbidity or precipitation, fruit and vegetable juice drinks will seriously affect its quality, and even lose their use value. Therefore, prevention of turbidity or precipitation in fruit and vegetable juice drinks is the important link of all manufacturing enterprises. It needs to be strictly controlled in the production process of fruit and vegetable juice drink.

- Treatment of production water. Reverse osmosis treatment of processing water strictly control the water pH value and conductivity, so as to achieve the fruit and vegetable juice processing water requirements.

- In the production of fruit and vegetable juice drink, clarification and filtration should be firstly carried out , and gelatin and tannin can be used to remove the suspended particles in the fruit and vegetable juice drink. In the current industrial production, the fruit and vegetable juice are generally heated (about 90°C) to inactivate the oxidase, then cooled down to 50°C, adding pectinase and keeping warm for 40minutes, the fruit and vegetable juice can be clarified. Using vacuum filtration method, filting with diatomite filter, the vacuum degree is controlled at about 84.6kPa.

- Homogeneous. In the fruit and vegetable juice drink enterprise, generally using colloid mill to homogenize, which can make the pulp grain reach below 0.002 millimeters.

- Sterilization. Fruit and vegetable juice drink should be sterilized before filling, which can adopt high temperature instantaneous sterilization.

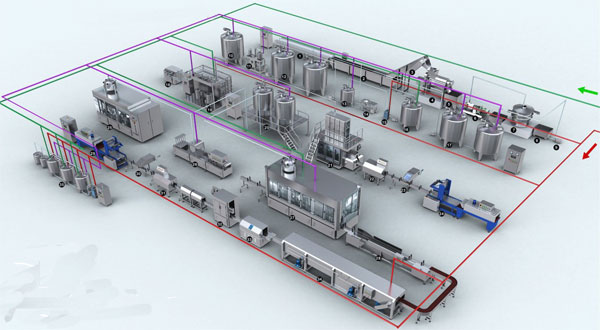

Building your own fruit and vegetable juice drink production line, Contact us now!

-lp.jpg)