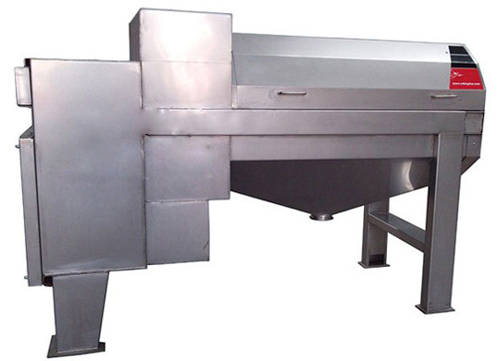

AGICO fruit pulping machines apply to different kinds of fruits including stone fruits(mango, peach, apricot), citrus(orange, lemon), berries(grape, pomegranate, strawberry), boiled and softened kernel fruits(apple, pears). It can accomplish the coring, pulping and separating work of fruit processing.

Features of AGICO fruit pulping machine

- Fruit pulp and residue are separated automatically

- It can work individually or connected to the juice production line

- The contact part with raw materials are made of superior stainless steel, meeting food hygienic standard.

Main structure of fruit pulping machine

AGICO fruit pulping machine is composed of a driver system, bearing block, sleeve, back and front cover, pulp blocking tray, cylinder, spline shaft, screen, scraper or beating bar, and rack, etc.

There are single track and double track two types. When use single track fruit coring and pulping machine to process stone fruits, just change to the corresponding rotor. The fruits is cored automatically, with the peel and pulp flowing to the next procedure. In terms of double-track fruit pulping machine, the two tracks adopt different rotors, which can separately carry out coring and pulping work, greatly improving the efficiency.

How dose fruit pulping machine work?

Kernel fruit processing

The pulping power is from an electric motor, who drive the rotor parts with a triangular belt. Fresh fruits are sent into the machine through the feed port, and transmitted to the beater by feed blades. The fresh fruits are pounded into pulps by beaters. Then, fruit juice and purees penetrate the holes on screen and got into the next procedure. Meanwhile, fruit kernels and residues are discharged from the slag hole. This is how fruit pulp and residue are separated.

Berries processing

When berries are put into fruit pulping machine from the feed port, there is a pulp blocking tray uniformly distributing them between the scraper and screen. Under the gyroscopic force of scraper and the guide from lead angle, raw materials move along the cylinder toward the outlet, in a shape of spiral. During their movement between the scraper and screen, raw materials are crushed under the centrifugal force. The juice and puree are squeezed through screen holes and get to the next procedure, while the peel and seeds are discharged from the slag hole. By these means, they automatically get separated. As for different varieties of berries, just install correspondent screen and adjust the lead angle of scraper. The fruit pulper can achieve different speed and the best pulping effect.

-lp.jpg)