Process technology of Making Grape Juice

The workflow of grape juice manufacture is as the following: raw materials—grape sorting—grape cleaning—desteming—crushing—heating for color distill—pressing—filtration—blending—clarification—heating—canning and sealing—sterilization—cooling.

Processing flow of Making grape juice

Select raw materials

Concord is regarded as the optimum fox grape for making grape juice. It is abundant in acid and bright in color, with distinctive taste. Concord grape juice look crimson as light go through, and appears fuchsia under reflected light. Concord grapes are excellent for processing. The grape juice presents stable property, who won’t lose color or generate precipitation under the process of sterilization and storage. In addition, other frequent varieties for making grape juice includes: Muscat, Ottawa, and Negra, etc.

The raw materials for making grape juice are required to be fresh and totally mature, presenting purple or black purple, with no decay, pests or disease. Immature grapes are inferior in color, flavor and taste, with too strong sour taste. Overripe grapes or grapes with mechanical damage are easy to give rise to yeast growth and distort the flavor. We supply specialized grape vibration separator, which transmits raw materials by high-frequency vibration. During the transmission, staffs can pick out the substandard grapes, stems, and impurities conveniently.

Grape cleaning

After removing the impurities and unqualified grapes, we need to clean the selected grapes thoroughly. A fruit bubble washing machine is needed to clean grapes massively. When putting grapes into fruit bubble washing machine, the rolling water keep them rotating and scour the surface to wash the dirt out. A fruit bubble washing machine can remove the impurities without do any damage to the fruits. We recommend to dip the grapes in potassium permanganate solution for 3 minutes and rinse them in flow water, which can achieve better cleaning effect.

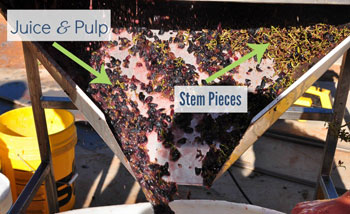

Desteming and crushing

The grape stems contains 1%-2% tannin, 0.5%-1.5% acid and bitter compounds, which would dissolve out astringency if heated together with grapes. Therefore, before crushing the grape stems must be removed.

Grape stemmer crusher is the key equipment in grape juice production line. It can separate stems from the grapes automatically, and keep the integrity of grapes at the same time. Equipped with adjustable stem blade, it can maximize the rate of exception, whose production capacity is greater than 5t/h. The nylon screen is acid, alkali and corrosion resistant.

After that, the destemed grapes are transmitted by scraper elevator to the broken extrusion device, where they are crushed into grape pulps. This grape breaking device is good at processing grapes with thick skins.

Heating for color distilling

Heat the crushed grape pulp up to 60-62.7℃, and keep this state for 15 min, so that the pigments in grape peels dissolve in the grape juice. This is an indispensible process for making red grape juice, while making white grape juice can omit this process.

Pressing and filtrating

To extract juice from grapes requires specialized grape juice extractor. This series screw extractor applies to extract juice from fermented grape residues. It adopts double screw structure and low speed extraction, promoting high juice yield. The pressure of corn plug in the outlet is adjustable, so is the moisture degree of grape peel and pomace. All the parts connecting with raw materials are made of high-resistance stainless steel.

We recommend to add 0.2% pectin enzyme and 0.2% refined wood fibers to promote the juice yield. After grape juice extraction, the crude juice requires filtration to remove the slag.

Juice blending

Add sugar liquor to raise the sugar degree of juice up to 16%. Then add 2% Partial tartaric acid solution of 3kg to every 100kg grape juice, in this way it keep the tartar from crystallizing.

Classification

Gelatin and tannin is the most common method. They are added according to the pectin and tannin content of the grape juice, usually 4-6 kg tannin for 100 kg fruit juice, and 6-10g gelatin after 8 hours. The best temperature for clarification if between 8℃ and 12℃.

Canning and sealing

Heat the clarified grape juice to 80℃, and fill it to pre-sterilized glass bottles. Then seal the bottles with caps.

Sterilization and cooling

Sterilize the grape juice with hot water at the temperature of 85℃. The sterilization time is 15 min, then the juice is cooled to 35℃ by subsection cooling.

-lp.jpg)