Fruits are rich in dietary fibers, vitamins, phytonutrients, and antioxidants, with no cholesterol. They can provide us with energy and improve our immunity. With more and more people realize the health benefits of fruits, various fruit products become popular. To prolong the shelf life of fruits, people invented canned fruits, dried fruits, and fruit juice powder.

What is fruit juice powder?

Fruit juice powders are concentrated fruit juice dehydrated by spray drying method. Its moisture content is 1%-3%. Besides, there are freeze drying and drum drying 2 methods.

Fruit juice usually have 85% water content. Making it into powders can reduce the volume and prolong its shelf life, and preserve the color, flavor, and tastes as much as possible.

The production process of fruit juice powder

The production of fruit juice powder is the production of concentrated fruit juice added with drying process. It can be divided into 3 parts:

- Raw materials pretreatment: fruit sorting, cleaning, crushing, heating, enzyme treatment.

- Fruit juice extracting: fruit pulping, juice extraction, clarification (for making clear juice), homogenization and degassing (to make cloudy juice).

- Juice processing: fruit juice concentration, drying, cooling, packing.

Spray drying process

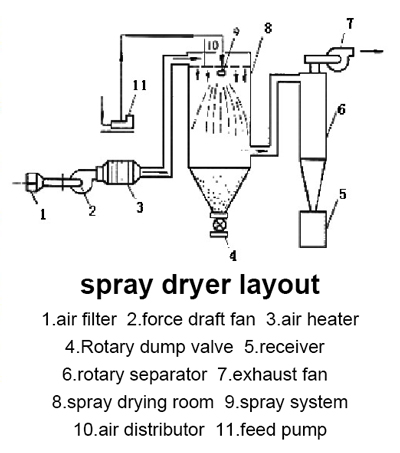

Spray dryer is used to produce milk powder and fruit and vegetable powder. Spray dryer is composed of a air heater, spray system, drying room, collecting system, and air blower for pressure supply and air suction.

In the drying process, the fruit juice and pulp are sprayed out in the form of fog droplets. Then they suspend in the hot air. During the contact with hot air, the moisture evaporate rapidly. After this process, the solution, emulsion or pulps can be dried into powders and granulates, with no need for the evaporation and crushing process.

The spray system has 3 types: Pressure spray, airflow spray and centrifugal spray. They adopt different working principle. Pressure sprayer require the least power consumption. But the nozzles are small and easy to block, not suitable for high-viscosity liquid and liquid with small particles. Airflow sprayer has high power consumption, but it has simple structure and wide application. Centrifugal sprayer applies to high-viscosity liquids and liquid with particles, but it has high manufacturing difficulty and cost.

The sketch of spray dryer

Applications of fruit juice powder

- Used as raw materials for making fruit juice and wine.

- Serve as food additives. It can not only improve the color, flavor and taste of food, but increase the nutritive value.

- Further process. Fruit peel, core, shell powders contain pectin and other substances, which can serve as raw materials for some food and medicines.

Fruit juice powder can be used to make instant powder mix, fruit cake, milk powder, sandwich biscuit, dietary supplements, infant food, puffed food, spices, pastries, cold snacks, and instant food. They can increase the added value of food.

Advantages of fruit powders

- With all water content removed, fruit juice powder has long shelf life.

- Low weight and volume can reduce cost for storage and transportation.

- Wide applications. Fruit juice powder can be used as a flavoring agent in cooking and various food.

-lp.jpg)