AGICO PET Bottle Filling Machine Introduction

PET bottle filling machine (also called hot filling machine) is a kind of 3-in-1 filling machinery, which integrates washing, filling, capping together, and is widely used for hot filling of PH<4.5 sensitive fluids such as milk, green tea, fruit and vegetable juices, and beverages in various types of PET bottles.

It is suitable for the hot filling of various juices and tea beverages and can be used for the filling of purified water and mineral water by replacing a small number of parts. The output is 5000-24000 bottles/hour, which can be selected by users. Using the advanced micro-negative pressure gravity filling principle, it fills quickly, steadily, and accurately. It is equipped with a perfect material return system, which can realize an independent gas return, not contact with materials, and reduce the probability of secondary pollution and oxidation of materials.

AGICO PET bottle-filling machine can meet the technical requirements of hot filling below 95 degrees Celsius. The filling valve and the material inlet and outlet pipelines have no sanitary dead ends and are equipped with a CIP system, and the RO water flushing device for the bottle mouth is provided before capping to ensure that there is no mold at the bottle mouth. It adopts a magnetic torque type capping head to realize the function of grabbing and capping. The whole machine adopts touchscreen control, PLC computer program control, inverter control, and other advanced technologies. PET bottle filling machine has the functions of automatic control of a capping system, automatic detection of filling temperature, high-temperature alarm of materials, low-temperature shutdown and automatic reflow, waiting for missing bottles, and stopping without caps.

AGICO PET bottle-filling machine combines the three functions of rinsing, filling, and capping on one machine, and the whole process is automated, which is suitable for filling fruit juice drinks and fruit tea drinks in high-temperature resistant polyester bottles, and also for filling carbonated beverages such as mineral water and purified water. This machine is made of high-quality SUS304 material, the key components are precision processed by CNC machine tools, and the whole machine adopts advanced photoelectric to detect the operation status of each component.

The main performance of the AGICO PET bottle-filling machine:

- The bottle feeding adopts an air-conveying device, which is fast and will not deform the bottle.

- The bottle mouth flusher adopts advanced block bottleneck technology to avoid contact with the threaded mouth, which is more hygienic. The bottles are conveyed using block bottleneck technology, so there is no need to adjust the height when changing the shape of the bottle. The filling adopts a valve lifting device, and the filling valve adopts a new type of micro-pressure filling principle, which is accurate.

- The cap sorting device is installed at a low level and fed horizontally.

- PET bottle three-in-one filling machine integrates rinsing, filling, and capping, and is developed according to the filling process requirements of juice and other beverages. The temperature of the filled liquid is generally around 82-85 degrees Celsius.

|

.jpg) |

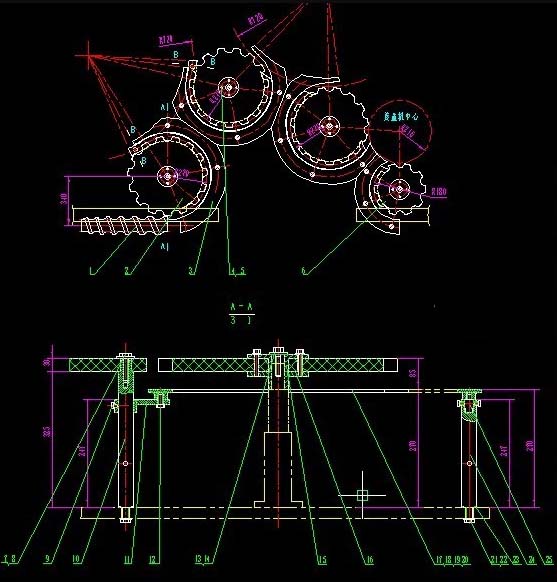

AGICO PET Bottle Filling Machine Structures

PET bottle filling machine is composed of rinser, filler, capper, frame, sealing window, main motor and transferring system, cap unscramble and electric control system etc.AGICO PET Bottle Filling Machine Features

- The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

- The machine has compact structure, complete control system, easy operation and high degree of automation.

- The parts contacting media are made of 304 and have no process blind angles to enable easy cleaning.

- The control system has the function of control producing speed, cap shortage detection, bottle block auto stop and production counting.

- High-speed high-volume, high precision filling valve, filling fast, accurate and non-liquid surface damage

.jpg)

Technical characteristics of AGICO PET bottle-filling machine:

a. Rinsing part

b. Filling part

c. capping part