Juice Homogenizer Introduction

Juice homogenizer is special equipment for making superfine emulsive liquid of liquid-liquid combinations or dispersed substance of liquid-solid combinations. This equipment is widely used in the fields of food, dairy, beverage, pharmaceutical, fine chemical and biological technology, scientific research and technology development. For food and beverage industry, it is widely applied for the production of UHT milk, pasteuried milk, yogurt, milk-based beverage, soy milk, peanut milk, pine-nut milk, etc.

|

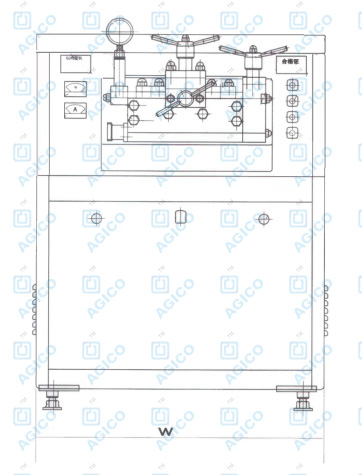

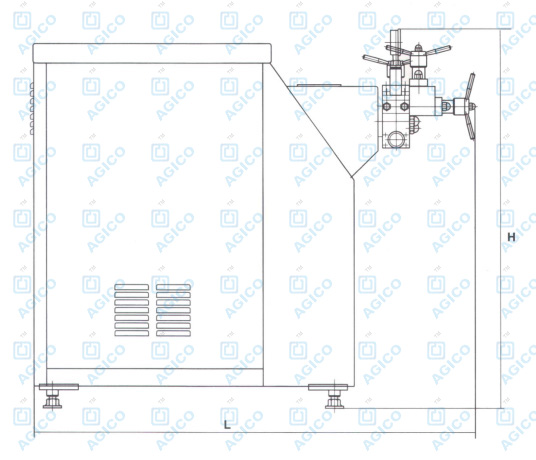

This equipment is composed of a frame, transmission box, pump body, pressure gauge, homogenizer, and other components. This machine is arranged vertically, the motor is installed in the frame, the gearbox is installed on the frame, and the pump body is connected to the gearbox.

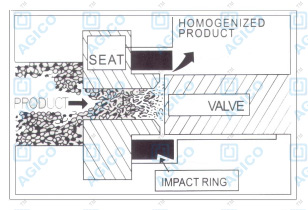

Juice Homogenizer Working Principle

The liquid at high speed passes through the capillary openings or special narrow slits. The result is disintegration of fat particles to 0.1-1.0 microns and its uniform distribution. Thus the homogenized milk has smooth mouth feel.

Juice Homogenizer Features

- Pure physical processes, can maintaining the original activity of productions.

- Homogenization pressure: 15-80MPa can choose according to different raw materials and processing need.

- Choosing different number of plungers, according to production yield.

- Noise of transmission is lower than noise of motor. The pointer of pressure meter is steady.

- Sealing material can work under less than 150oC, and the parts touching material is made of stainless steel which can stay up to the acid and alkali. All of valves and plungers are made of special material, so they are durable and inexpensive. The bearing is also durable because it is made of special alloy material, which is the more friction, the more hardness.

| Model | Rated flow (l/h) | Rated pressure(Mpa) | Working pressure(Mpa) | Power(Kw) |

|---|---|---|---|---|

| MGJ500/25 | 500 | 25 | 20 | 5.5 |

| MGJ500/60 | 500 | 60 | 50 | 11 |

| MGJ1000/25 | 1000 | 25 | 20 | 7.5 |

| MGJ1000/40 | 1000 | 40 | 35 | 15 |

| MGJ2000/25 | 2000 | 25 | 20 | 15 |

| MGJ2000/40 | 2000 | 40 | 35 | 30 |

| MGJ5000/25 | 5000 | 25 | 20 | 45 |

| MGJ5000/40 | 5000 | 40 | 35 | 55 |

| MGJ10000/35 | 10000 | 35 | 28 | 110 |

| MGJ10000/40 | 10000 | 40 | 32 | 132 |

Installation of The Juice Homogenizer

- The machine does not need to be fixed by foot screws and can be placed directly on the ground, but the ground must be firm and flat.

- There are several gaskets attached to the bottom support feet, and rubber shock pads are placed underneath, which can further reduce noise and improve stability.

- The inlet and outlet ports of the pump body are connected with other systems by polyethylene hose, to observe the inlet and discharge conditions. It can also be connected with stainless steel pipes, and valves are not allowed to be installed on the outlet pipeline of this machine to prevent the pipe from bursting.

- The cooling water input is connected to the inlet pipe by a polyethylene hose, accompanied by a switch to control the cooling water flow.

- After the power supply is connected, the rotation direction of the pulley must be clockwise or in the direction of the signage arrow to ensure that the rotating parts are fully lubricated.

Maintenance of The Juice Homogenizer

- The lubricating oil should be replaced after 750 operating hours or the color becomes milky white, and the replacement method is as follows:

- Unscrew the oil drain hole nut installed in the gearbox, use a plastic pipe to lead out the waste oil (placed in the oil drum, after precipitation, the above clean oil can still be reused), tighten the oil drain hole nut, it is recommended to start the machine for 5 minutes to rinse with diesel fuel in the gearbox at 0 pressure, since all drive parts are thoroughly cleaned, drain the diesel and inject new lubricating oil.

- The machine is running for a while, if there is an abnormal sound, you should pay attention to tightening the fasteners of the transmission part and tightening the transmission belt.

- The bearings in the motor are coated with oil and can be maintained according to the general maintenance method of the motor.

Workshop

|

|

How to Choose a Juice Homogenizer

- Minimum trial amount: the smaller the better, you can save materials.

- Processing effect: Of course, the user hopes to make the material, one is to be able to reach the nanoscale level, and the other is the nanoscale at the same time, the distribution is very uniform, rather than some particles are already dozens of nanometers, and some are still micron-level.

- Then consider the noise, safety, and other aspects of a homogenizer.